Cable trunking is a technical-sounding way of hiding or organizing cables, sort of like how furniture trunks hold clothing. It may be made of plastic, galvanised steel or aluminium and is often used in locations where cabling runs are likely to be exposed or at least partially visible. It can also be installed in non-dropped ceilings to keep large runs of cabling neatly organised.

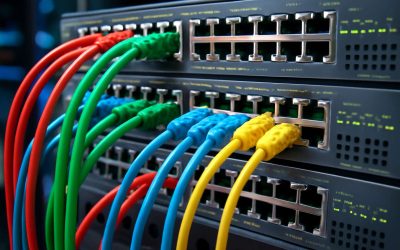

A variety of sizes are available for use in different applications, such as running telephone or data wires in a office building, or connecting CCTV cameras and other security equipment to an internet hub or distribution box. There are also fireproof trunking options for use in areas where safety is a concern.

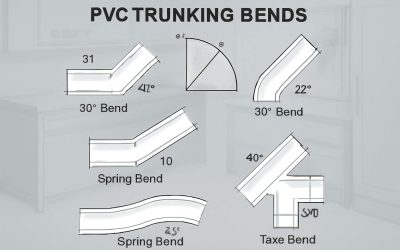

When installing cable trunking, the first thing to consider is what type of materials are best for your particular needs. Galvanised steel is an excellent choice for outdoor and underground cable runs because of its high resistance to corrosion, while aluminium is a great choice for many lightweight applications where aesthetics are important. There are also a variety of fittings available, including those that allow for easier access or the attachment of labels for identification.

Most types of trunking are available in a range of colours, so it’s easy to find one that matches the rest of your wiring system. Some can even be labelled for specific purposes, such as power, data or fire protection. They can also be fitted with a hinge lid to prevent accidental cable tampering.

There are a number of factors that can affect the capacity of a trunking system, such as installation method, design current, grouping factor and number of current-carrying conductors. Choosing the correct size is crucial to ensure that trunking systems can cope with the amount of cable they will be carrying. In the Fifteenth Edition of the IEE Wiring Regulations, there is a table in Appendix 12 that provides a series of factors for each type of conduit or trunking, which can be used to calculate capacities.

Another benefit of using cable trunking is that it can help to reduce the overall cost of a wire management system by allowing for the consolidation of multiple communication wires into a single larger wire. This can significantly increase the overall bandwidth and capability of a network, and reduce the number of connections required for each wire.

The global market for cable trunking is expected to grow rapidly in the next decade, thanks to rising demand for new and advanced communication systems. This includes the Internet of Things (IoT), 5G and smart building systems, which all require a structured cabling system to organize and manage cables.

Cable trunking components are usually pre-assembled at the PFLITSCH plant in Huckeswagen, and dispatched as scheduled to your installation site. This just-in-time service helps to optimise process times, minimise storage requirements and reduce shipping costs. The complete shipment also contains all necessary parts lists and detailed technical drawings to enable quick and accurate assembly on-site.

0 Comments