Cable trunking (also known as conduit or ducting) is used to route electrical cables and provide a safe and tidy solution for wire management in commercial, industrial, and residential settings. It is usually made from strong and lightweight plastics such as polyvinyl chloride, and comes in a wide variety of sizes, shapes, and forms. Some types of cable trunking are specifically designed to fit into tight spaces, allowing them to be installed in areas where space is limited.

The main purpose of cable trunking is to protect wiring from damage or tampering. It also helps to keep the wiring organized and provides an easy way for electricians to access it. In addition, it can help to reduce the risk of accidents resulting from unintentional contact with wiring. There are a number of different types of cable trunking available, including plastic pvc trunking, metal conduit and wiring ducts, and steel wire baskets. Each type has its own unique benefits, so it’s important to choose the right one for your particular needs.

PVC cable trunking is an excellent option for many residential applications. It is quick and easy to install, and can be a cost-effective choice for home renovations. It can also be a good alternative to traditional metal conduit in certain cases. PVC trunking is also available in a wide range of colors, making it easy to match your existing décor.

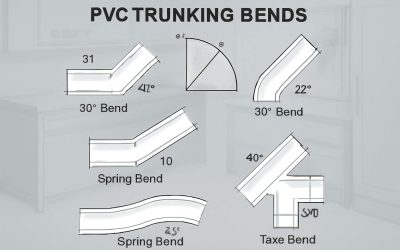

Another benefit of pvc trunking is that it can be easily cut to size with a hacksaw, making it possible to accommodate any space. It is also flexible, allowing it to bend around corners and other obstacles without damaging the cable or fittings. It is also available in a wide range of lengths, so you can find the perfect fit for any space.

A wide range of accessories is also available to use with pvc trunking. For example, there are cable ties that can be used to secure the trunking to walls and floors, and covers that can be fitted over cut ends or open holes in the wall. Additionally, there are splicing kits that can be used to connect two pieces of trunking together, and a variety of mounting clips and supports that can be attached to the walls or floor.

Depending on the type of trunking you choose, you may need different tools for installation. For example, some types are self-adhesive and can be fitted without needing to drill or screw into place. Other types of trunking are designed to snap together, and may require the cable to be run through beforehand. Heavier types of trunking or conduits, such as those made from galvanised steel, may need screws or other fasteners to ensure they stay in place.

The global cable trunking market is growing rapidly, with North America holding the largest revenue share. This is largely due to increasing construction and renovation activities, as well as the popularity of smart building technologies and energy-efficient buildings. It is also important to note that while trunking and conduit provide an effective means of protecting wires, they are not a substitute for proper installation and testing of electrical systems.

0 Comments