Understanding Trunking for Cable Management

What is Trunking and Its Uses – Explanation of trunking and its importance in electrical installations

In the wild world of electrical installations, trunking 50mm x 25mm isn’t just a fancy accessory—it’s the unsung hero of tidy, safe cable management. Think of it as the duct tape of the electrical universe, holding chaos at bay and transforming a jumble of wires into a sleek, organized masterpiece. Trunking plays a vital role in protecting cables from dust, moisture, and accidental damage, ensuring longevity and safety in every corner of your space.

For those in South Africa seeking a reliable solution, understanding the importance of trunking 50mm x 25mm is crucial. Its dimensions are perfect for running multiple cables in commercial or residential settings, offering ample space without looking like a highway for wires. Whether it’s for a new installation or an upgrade, choosing the right trunking ensures your wires stay secure, accessible, and visually unobtrusive. After all, who wants a wiring nightmare when a simple trunking can do the trick?

- Ease of installation and maintenance

- Enhanced safety and protection

- Neat appearance with minimal effort

Types of Trunking Materials – Overview of different materials such as PVC, metal, and plastic

Understanding trunking for cable management involves more than just selecting a box to hide wires; it’s about choosing the right material that aligns with safety, durability, and aesthetic needs. Trunking 50mm x 25mm, in particular, offers a versatile solution that balances size and practicality, but the material composition can significantly influence its performance.

Different types of materials such as PVC, metal, and high-grade plastics each bring unique advantages to the table. PVC trunking 50mm x 25mm is lightweight, cost-effective, and resistant to corrosion—making it ideal for most residential and commercial environments. Metal trunking, often made from steel or aluminium, provides enhanced strength and security, perfect for industrial settings where cables face harsher conditions. Plastic trunking, on the other hand, offers flexibility and ease of installation, making it a popular choice for quick upgrades or temporary setups.

Choosing the right material isn’t just about appearance; it impacts the safety, longevity, and overall integrity of your electrical installation. For instance, trunking 50mm x 25mm in PVC is often preferred for its simplicity and affordability, while metal options are favored where extra protection is needed. Understanding these distinctions ensures your wiring remains protected and compliant with local standards, especially in dynamic South African environments.

Benefits of Using Trunking – Advantages including safety, organization, and aesthetics

In the shadowy realm of electrical craftsmanship, the true power lies not just in the wires we conceal, but in the silent guardians—trunking 50mm x 25mm—that hold our worlds together. When properly chosen, this modest conduit becomes a fortress of safety, shielding delicate cables from the chaos of everyday life. Its sleek form lends an air of order amid the chaos, transforming tangled messes into pristine corridors of clarity.

The benefits of using trunking 50mm x 25mm extend beyond mere aesthetics; it is a linchpin of safety and longevity. By encasing cables within its sturdy embrace, it reduces the risk of accidental damage, electrical faults, and fire hazards. Moreover, the clean lines of trunking enhance the visual harmony of any space, whether in a bustling industrial site or a quiet South African home. A well-installed trunking system whispers a promise of durability, standing resilient against the test of time and the corrosive elements of the environment.

- Protection from physical damage and environmental elements

- Enhanced safety by reducing electrical hazards

- Improved aesthetic appeal through organized wiring

In a landscape where chaos often reigns, the strategic use of trunking 50mm x 25mm offers a sanctuary of order and security. Its presence ensures that cables are not only hidden but also fortified—shielded from the relentless march of time and nature’s fury. For those who seek a harmonious blend of form and function, this conduit is more than a mere accessory; it is an essential guardian of the electrical realm. And in South Africa’s rugged terrains, where reliability is paramount, the choice of trunking material and size becomes a decision rooted in both safety and aesthetic integrity.

Features of 50mm x 25mm Trunking

Dimensions and Compatibility – Details on size specifications and suitability for various cables

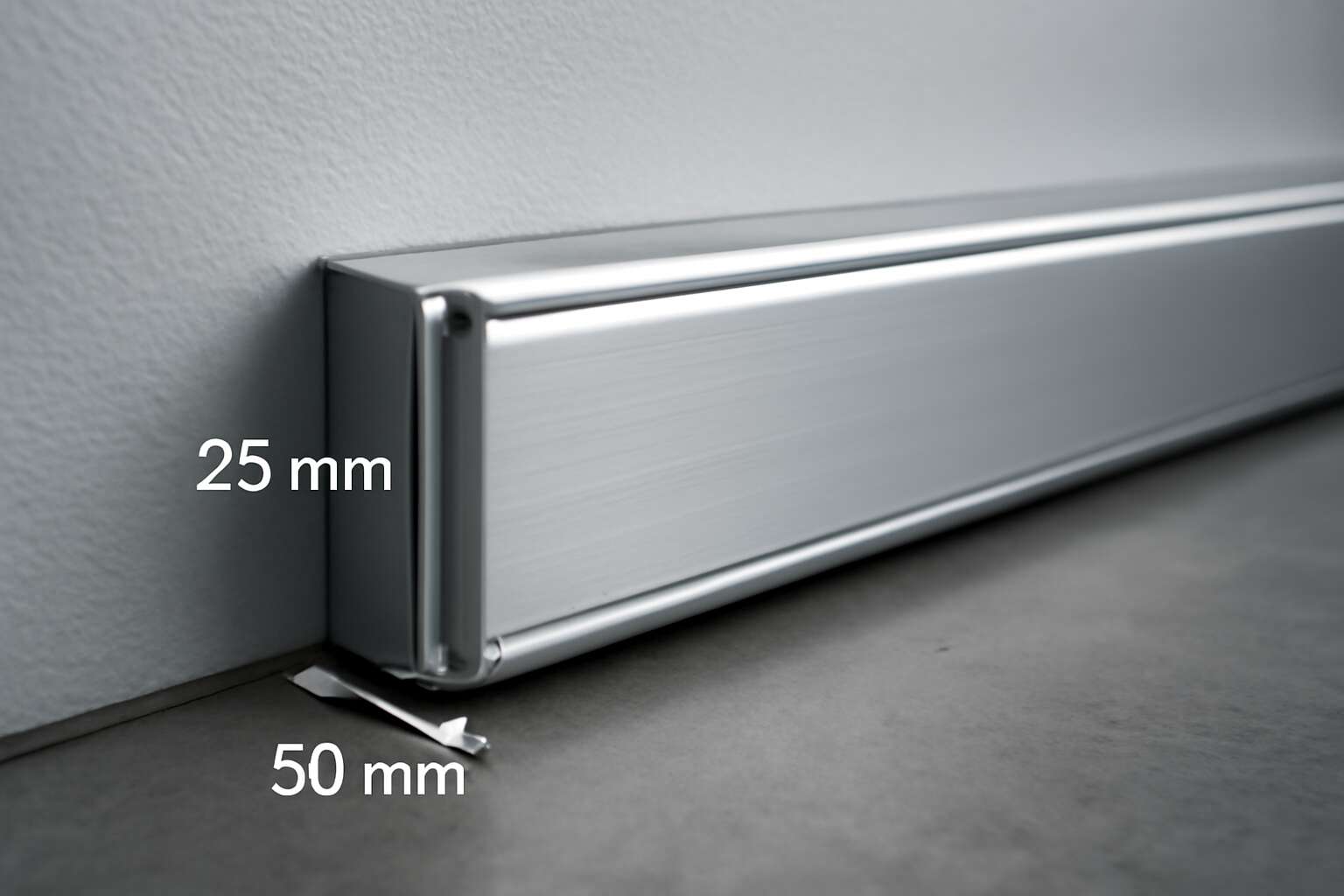

When selecting the ideal trunking 50mm x 25mm, understanding its dimensions is crucial for seamless integration into complex electrical infrastructures. This size, with a width of 50mm and a height of 25mm, strikes a delicate balance—robust enough to accommodate a variety of cables while maintaining a tidy, unobtrusive profile. Its compact yet versatile form makes it particularly suitable for environments where space is at a premium, such as commercial offices or residential developments across South Africa.

Compatibility is another critical factor. The trunking 50mm x 25mm is designed to support multiple cables, including power, data, and communication lines, without sacrificing accessibility or safety. Its internal capacity allows for a range of cable diameters, typically up to 15mm in diameter, making it adaptable to diverse wiring needs. For added convenience, many models feature removable covers and modular fittings that facilitate easy installation and maintenance.

In terms of suitability, this trunking size is often favored in scenarios requiring discreet cable management, yet ample space for future expansion. Whether used in retrofit projects or new builds, its dimensions ensure it can be seamlessly incorporated into wall cavities or mounted along surfaces, providing a neat and professional finish. The precise dimensions not only enhance compatibility but also contribute to the overall safety and longevity of the electrical system.

Design and Construction – Description of structural features, wall thickness, and durability

The structural design of trunking 50mm x 25mm embodies a meticulous balance of strength and finesse, ensuring enduring performance in bustling electrical landscapes. Crafted with precision, the wall thickness typically ranges between 1.0mm and 1.5mm, providing a resilient shell that withstands daily wear and tear. This durability is essential, especially in environments where vibrations and accidental impacts are unavoidable, such as busy commercial spaces or residential complexes across South Africa.

Its robust construction not only guarantees longevity but also facilitates a seamless installation process. The material used — whether high-grade PVC or galvanized steel — enhances its capacity to resist corrosion and environmental factors. For added versatility, many models feature a modular design, allowing for customizable fittings and easy access points that simplify maintenance and future upgrades.

Furthermore, the design incorporates features like snap-fit covers and pre-drilled holes, which streamline the assembly process, reducing installation time and ensuring a secure, professional finish. The trunking 50mm x 25mm is truly a testament to engineering precision — a sturdy yet elegant solution for tidy, safe, and future-proof cable management in South Africa’s dynamic infrastructure landscape.

Color and Finish Options – Available colors and surface finishes for aesthetic integration

When it comes to integrating trunking 50mm x 25mm into your electrical setup, the aesthetic options are just as vital as their structural qualities. These trunking systems are available in a variety of colors and finishes, allowing for seamless blending into any environment—be it a sleek office corridor or a warm residential interior. The right color choice can elevate the overall look, transforming what might be seen as just functional into a feature that complements your space.

For environments demanding a polished appearance, surface finishes such as smooth glossy or matte textures are popular, offering both durability and a refined look. Additionally, classic hues like neutral grey or white are often preferred for their ability to harmonize with existing decor. The versatility of trunking 50mm x 25mm ensures it can be customized to match or contrast with walls, furniture, or branding elements, making it an invaluable component for professional installations across South Africa.

- Color options include neutral tones like white, grey, and black, which are ideal for discreet cable management.

- Surface finishes range from matte to high-gloss, providing choices that suit different aesthetic preferences.

- Some models offer textured surfaces that resist fingerprints and scratches, perfect for high-traffic areas.

This array of colors and finishes not only enhances the visual appeal but also ensures that trunking 50mm x 25mm can be tailored to meet specific project requirements, guaranteeing both form and function are achieved with ease. Whether installed in a bustling commercial hub or a cozy home, these aesthetic options make the trunking system a versatile and stylish solution for cable management in South Africa’s diverse environments.

Applications of 50mm x 25mm Trunking

Residential Electrical Installations – Use in homes for organized wiring and safety

In South African homes, the silent guardian of electrical safety often goes unnoticed—until a fault occurs. The versatility of trunking 50mm x 25mm makes it an indispensable component in residential electrical installations. Its robust dimensions provide ample space for organized wiring, reducing the risk of accidental damage or electrical shorts that could threaten household safety.

Beyond mere protection, trunking 50mm x 25mm plays a pivotal role in maintaining a neat, professional appearance within living spaces. Whether concealing cables behind walls or running along ceilings, it ensures that wiring remains securely contained and visually unobtrusive. For added flexibility, this trunking size accommodates various cable types, including power, data, and communication lines—making it highly adaptable for modern homes.

In some cases, installation of trunking 50mm x 25mm can be a strategic choice to streamline future upgrades or repairs. Its spacious interior allows for easy threading of new cables, minimizing disruption and maintaining the integrity of the electrical system. This size strikes a perfect balance between capacity and discreetness, making it a favored choice for residential projects aiming for safety, orderliness, and aesthetic appeal.

Commercial and Industrial Use – Application in office buildings, factories, and data centers

In the shadowed corridors of commerce and industry, where the hum of machinery intertwines with the flickering glow of data centers, the humble yet formidable trunking 50mm x 25mm stands as an unyielding sentinel. Its robust dimensions are no mere accident—they embody a strategic design to tame the chaos of cables in the labyrinthine spaces of office buildings, factories, and data hubs. Here, in these modern catacombs, the trunking 50mm x 25mm weaves a silent web of order amidst the chaos of power and data lines, safeguarding the integrity of vital systems.

Within these environments, the application of trunking 50mm x 25mm transcends simple containment. Its interior capacity allows for a meticulously organized array of cables, from heavy-duty power lines to delicate data conduits. This ensures not only safety but also expedites future upgrades and maintenance. For instance, in data centers, where every millisecond counts and cable management is paramount, the trunking 50mm x 25mm provides a seamless conduit for evolving technology. The durability of its construction withstands the tumult of industrial environments, standing resilient against the relentless march of time and wear.

- Strategic routing of cables to minimize interference and maximize safety.

- Facilitating easy access for repairs or upgrades without disrupting entire systems.

- Providing a sleek, professional aesthetic that enhances the industrial ambiance.

In the realm of commercial and industrial installations, this size of trunking becomes more than a mere conduit; it is a silent guardian of operational harmony. Its adaptability and strength make it an essential element for those who demand precision, safety, and efficiency. The application of trunking 50mm x 25mm echoes the dark poetry of order within chaos, a testament to the craftsmanship that underpins modern infrastructure’s silent backbone.

Renovation and Upgrades – Benefits for upgrading existing wiring systems

Upgrading existing wiring systems in commercial and industrial settings can feel like navigating a labyrinth of electrical chaos—until the trusty trunking 50mm x 25mm enters the scene. Its generous interior space makes it the perfect vessel for replacing outdated conduits, offering a seamless upgrade that enhances safety and organization. When modernizing factories or data centers, the ability to efficiently reroute cables without extensive disruption becomes invaluable. The trunking 50mm x 25mm simplifies this process, providing a sturdy framework that accommodates future expansion and technological advancements.

Incorporating trunking 50mm x 25mm into renovation projects offers several notable benefits. It facilitates strategic cable routing, minimizing interference and optimizing system performance. Additionally, its modular design allows for quick access during repairs, reducing downtime significantly. For those seeking a professional aesthetic, the sleek finish of this trunking size lends a polished look to industrial environments—making safety, efficiency, and visual appeal harmoniously coexist.

Installation and Maintenance

Installation Tips and Best Practices – Step-by-step guidance for secure and efficient setup

In the intricate dance of electrical installation, the importance of precise and reliable trunking 50mm x 25mm cannot be overstated. A meticulously executed setup ensures not only safety but also longevity, transforming chaotic wiring into a symphony of order and efficiency. When installing trunking 50mm x 25mm, attention to detail becomes paramount, especially in environments where space constraints and future scalability demand intelligent planning. The process begins with selecting the right mounting surface, followed by securing the trunking firmly to prevent unwanted movement or exposure to environmental stresses.

For optimal results, consider the following installation tips and best practices. First, always measure the entire length of the run to ensure accurate cuts and alignment. Use quality fastening hardware to guarantee durability, and avoid over-tightening which can compromise the material’s integrity. To facilitate seamless cable management, plan the layout to include access points, junctions, and bends that adhere to the minimum bend radius for cables. When working with trunking 50mm x 25mm, a step-by-step approach can significantly streamline the process:

- Mark the installation pathway clearly on the wall.

- Cut the trunking sections precisely to fit the designated route.

- Secure the trunking to the wall at regular intervals, typically every 500mm.

- Use appropriate fittings and connectors for corners and junctions.

- Ensure all cables are neatly laid within the trunking, avoiding overcrowding to facilitate heat dissipation and ease of future maintenance.

Maintaining the integrity of the trunking 50mm x 25mm during installation is vital. Regular inspection during the setup process can preempt issues like misalignment or insufficient fastening, which could compromise the system’s safety and performance. Proper installation not only fosters a secure environment but also simplifies future upgrades or repairs, reinforcing the value of investing time in following best practices from the outset. Such meticulous attention to detail elevates the overall electrical infrastructure—turning a simple conduit into a resilient pathway for reliable power distribution.

Tools Needed for Installation – List of necessary tools and safety equipment

In the shadowed corridors of electrical craftsmanship, the tools you wield can turn chaos into order—or chaos into chaos. For the installation of trunking 50mm x 25mm, having the right arsenal is not just a matter of convenience but a necessity for ensuring safety and longevity. A well-equipped toolbox becomes your trusted ally in this meticulous dance, safeguarding against the unseen perils lurking behind walls.

At the core of your kit should be a sturdy measuring tape and a reliable marker—precision begins here. Cutting tools such as a fine-tooth hacksaw or a dedicated trunking cutter will ensure clean, accurate sections that fit seamlessly along your designated pathway. For fastening, a drill with appropriate bits and a set of wall anchors or screws are indispensable. Remember, the integrity of the trunking 50mm x 25mm hinges on secure attachment, especially in environments where vibration or environmental stresses threaten to loosen your setup.

Safety equipment is the silent sentinel of every professional installer. A pair of insulated gloves, safety goggles, and dust masks protect against debris and accidental injury. When working in confined or elevated spaces, harnesses or scaffolding might be necessary to maintain stability. To streamline the process further, consider using a set of fittings, connectors, and junction boxes—these facilitate seamless transitions and future upgrades within the trunking system.

- Measuring tape

- Marker pen

- Hacksaw or trunking cutter

- Drill and appropriate bits

- Wall anchors and screws

- Insulated gloves and safety goggles

- Dust mask

Choosing the correct installation and maintenance tools for trunking 50mm x 25mm ensures that every cable laid within is shielded from the corrosive grip of time and the unpredictable whims of the environment. In the end, it is a dance of precision and protection—an art form woven into the very fabric of modern electrical infrastructure.

Maintenance and Longevity – Advice on cleaning, inspections, and prolonging trunking life

Proper maintenance of your trunking 50mm x 25mm is essential to keep your electrical infrastructure performing at its peak. Over time, dust and debris can settle within the channels, potentially causing overheating or damage to the cables. Regular cleaning with a soft brush or damp cloth can prevent buildup and extend the life of the trunking. Additionally, periodic inspections help identify any signs of wear, corrosion, or loose fittings before they become costly repairs.

To ensure longevity, it’s wise to keep an eye out for cracks or deformations, especially in high-traffic or industrial environments. When needed, replacing damaged sections promptly can save you from a domino effect of failures. Remember, a well-maintained trunking 50mm x 25mm not only safeguards your cables but also preserves the aesthetic integrity of your installation.

For optimal durability, consider using fittings and connectors that match the material and environment. Here’s a quick overview:

- Inspect regularly for corrosion or physical damage

- Clean channels to prevent dust accumulation

- Ensure all fittings and junction boxes are secure

- Replace worn or damaged sections immediately

Adopting these simple habits transforms your trunking system from a neglected relic into a resilient backbone of your electrical setup, ensuring it withstands the test of time and environmental challenges.

Buying Guide for 50mm x 25mm Trunking

What to Look for When Purchasing – Key features, quality, and compliance standards

When selecting the ideal trunking 50mm x 25mm, understanding what truly matters can make all the difference between a fleeting fix and a lasting solution. The right trunking should seamlessly blend durability with practicality, ensuring your electrical installations are both safe and visually unobtrusive.

Key features to consider include the material quality—whether PVC or metal—since this impacts longevity and resistance to environmental factors. Compliance with standards such as SANS or IEC is non-negotiable; these benchmarks guarantee the trunking 50mm x 25mm meets rigorous safety and performance criteria. A robust construction with adequate wall thickness enhances structural integrity, especially when accommodating multiple cables or heavy-duty use.

Aesthetics may seem secondary, but the available color options and finishes can significantly influence integration into residential or commercial spaces. In environments prone to wear or moisture, selecting trunking with high-quality finishes extends its lifespan and maintains a professional appearance. Balancing these aspects—material, compliance, durability, and design—ensures that your investment in trunking 50mm x 25mm is both strategic and future-proof.

Cost Factors and Budgeting – Pricing considerations and value for money

In the realm of electrical installations, where safety and efficiency dance a delicate ballet, the cost of trunking 50mm x 25mm can often influence the choice of a project’s backbone. Price should never be the sole arbiter, yet understanding the factors behind the cost reveals a tapestry woven with quality and longevity. The materials—be it resilient PVC or robust metal—play a pivotal role in determining the initial investment and ongoing durability.

When budgeting for trunking 50mm x 25mm, consider the following elements that impact pricing:

- Material quality and finish—high-grade finishes and corrosion-resistant metals command a premium but promise extended lifespan.

- Compliance with standards such as SANS or IEC—certified trunking guarantees safety and performance, often reflected in higher costs.

- Design complexity and wall thickness—more intricate construction and thicker walls enhance strength, but may elevate the price.

While it might be tempting to focus solely on the lowest bid, investing in trunking 50mm x 25mm that offers superior value for money ensures your electrical system remains resilient and adaptable. Consider the long-term savings derived from a product that withstands environmental challenges without frequent replacement or maintenance. After all, a carefully chosen trunking is an investment in both safety and seamless functionality, transforming mundane wiring into a silent guardian of your space’s integrity.

Where to Buy Reliable Trunking – Recommended suppliers, online stores, and local distributors

In a landscape where electrical safety and reliability are paramount, sourcing the right trunking 50mm x 25mm can feel like navigating a labyrinth of choices. The secret to unlocking a seamless installation lies not just in price, but in discovering suppliers who prioritize quality and consistency. Trusted brands and reputable online stores provide an assurance of durability, ensuring that your investment withstands South Africa’s diverse environmental conditions.

For those embarking on a project or upgrading existing systems, turning to well-established local distributors can save time and guarantee compliance with standards like SANS and IEC. Many suppliers offer a curated selection of trunking 50mm x 25mm, featuring various finishes and materials suitable for residential, commercial, and industrial environments. To streamline your search, consider these recommended sources:

- Authorized electrical wholesalers with a proven track record in safety standards

- Specialist online stores offering detailed product specifications and customer reviews

- Local hardware retailers that provide immediate access and personalized advice

Whether you prefer the convenience of online shopping or the tactile assurance of visiting a local distributor, choosing the right supplier ensures your trunking 50mm x 25mm will serve as a resilient backbone for your electrical network. Remember, a reliable source not only supplies quality but also offers after-sales support, making your investment both secure and worthwhile.

Regulations and Standards

Electrical Safety Standards – Compliance with BS, IEC, or local regulations

When it comes to electrical safety standards, compliance isn’t just a bureaucratic hoop to jump through—it’s the backbone of a secure and reliable installation. For those installing trunking 50mm x 25mm, adhering to local South African regulations, as well as international standards like BS and IEC, is non-negotiable. These regulations are designed to ensure that your wiring system can withstand the rigours of daily life while minimizing the risk of fire or electrical faults.

Most importantly, choosing trunking 50mm x 25mm that meets these standards guarantees compatibility with a wide range of cables and accessories, safeguarding both property and personnel. Remember, a compliant installation isn’t just about ticking boxes; it’s about investing in peace of mind. For a project that stands the test of time, always verify that your trunking meets the necessary safety standards—quality compliance isn’t just a suggestion, it’s a necessity.

Installation Code Requirements – Legal considerations for trunking installation

When it comes to installing trunking 50mm x 25mm, understanding the legal landscape is essential. South African electrical regulations, along with international standards like BS and IEC, set the foundation for safe and compliant wiring systems. These regulations are not mere bureaucratic hurdles; they are vital safeguards that protect property and lives. Ensuring your trunking 50mm x 25mm meets these standards is crucial for a hassle-free installation that withstands the demands of daily use.

Legal considerations for trunking installation revolve around adherence to specific codes of practice. In South Africa, regulations mandate that trunking systems must be properly rated for the environment, support cable capacities, and be correctly installed to prevent hazards. To streamline compliance, consider the following:

- Verification that the trunking 50mm x 25mm complies with local South African standards, such as SANS 10142.

- Confirmation that materials meet IEC or BS safety standards for durability and fire resistance.

- Proper documentation and certification from suppliers to validate compliance during inspections.

Beyond safety, legal compliance also influences the long-term viability of your electrical system. Failing to meet these requirements can lead to costly rework, penalties, or even jeopardize insurance claims. For those deploying trunking 50mm x 25mm in commercial or industrial environments, an understanding of these regulations isn’t optional—it’s fundamental to responsible project management and peace of mind. Navigating these legal intricacies ensures that your installation is both safe and future-proof, reinforcing the importance of choosing compliant trunking solutions.

Environmental and Fire Safety – Materials compliance with safety standards

When it comes to installing trunking 50mm x 25mm, compliance with environmental and fire safety standards is non-negotiable. Materials used in trunking systems must meet rigorous safety standards to prevent hazards and ensure durability. Fire-resistant properties are especially critical, as subpar materials can rapidly escalate risks during a fire incident. Certified trunking 50mm x 25mm, compliant with IEC or BS standards, guarantees that your wiring remains protected under adverse conditions.

Understanding the importance of materials compliance, South African regulations require that all trunking systems adhere to local standards such as SANS 10142. This ensures that the product has been tested for fire safety, durability, and environmental impact. To verify compliance, always request proper documentation and certification from suppliers. These records serve as proof that the trunking 50mm x 25mm you choose aligns with international safety standards and local legal requirements.

In addition to safety, environmental considerations play a pivotal role. Opt for trunking made from eco-friendly, recyclable materials to reduce your project’s carbon footprint. The right choice of materials not only safeguards property and lives but also contributes to sustainable practices. By selecting compliant, high-quality trunking 50mm x 25mm, you’re investing in a solution that offers longevity, resilience, and peace of mind in any installation environment.

- Fire-resistant properties

- Environmental sustainability

- Certification and compliance documentation

Environmental Impact and Sustainability

Eco-friendly Material Options – Biodegradable and recyclable trunking materials

In a world increasingly obsessed with saving the planet, the choice of trunking 50mm x 25mm isn’t just about neat wiring—it’s about making a statement. Eco-friendly materials, such as biodegradable plastics or recyclable metals, are transforming the way we think about electrical infrastructure. These sustainable options not only reduce the carbon footprint but also align with global efforts to combat environmental degradation. Imagine a trunking that degrades harmlessly after its useful life—no more piling up in landfills or contributing to the ever-growing mountain of waste.

Opting for biodegradable or recyclable trunking materials is more than a trend; it’s a necessity. These eco-friendly options often come with certifications that ensure they meet stringent fire and safety standards, providing peace of mind alongside environmental benefits. For those who prioritize sustainability, numerous manufacturers now offer trunking 50mm x 25mm made from recycled plastics or natural fiber composites—turning a simple conduit into a beacon of responsible innovation.

- Biodegradable plastics that break down within a few years, leaving no harmful residues.

- Recyclable metals such as aluminum and steel, which can be reprocessed endlessly without quality loss.

- Materials that meet strict environmental standards, ensuring compliance with South African safety and sustainability regulations.

By choosing eco-friendly trunking 50mm x 25mm, electrical professionals can champion sustainability while maintaining top-tier safety and durability. It’s a win-win scenario—less waste, lower environmental impact, and a future-proof installation that respects the planet’s precious resources.

Waste Management and Recycling – Proper disposal and recycling practices

In a world where environmental consciousness is no longer optional but essential, the way we handle waste from electrical infrastructure plays a pivotal role. Choosing eco-friendly trunking 50mm x 25mm isn’t just about securing cables—it’s a statement about responsibility. Proper waste management and recycling practices ensure that these materials don’t end up in overflowing landfills, where they can leach harmful substances into our soil and water.

Recycling trunking 50mm x 25mm made from recyclable metals like aluminum or steel allows these materials to be reprocessed endlessly, conserving natural resources and reducing energy consumption. Meanwhile, biodegradable plastics, which break down harmlessly within a few years, offer a sustainable alternative that aligns with global efforts to lower carbon footprints. Adopting these practices helps preserve South Africa’s environment for future generations.

Effective disposal and recycling of trunking involve adhering to local regulations and collaborating with certified waste management services. By doing so, electrical professionals contribute to a circular economy—where materials are valued, reused, and kept out of landfills. Consider this:

- Separate used trunking 50mm x 25mm from general waste.

- Partner with recycling facilities experienced in handling electrical waste.

- Opt for materials with environmental certifications that guarantee safe disposal and reprocessing.

Embracing these principles ensures that eco-friendly trunking not only meets safety standards but also champions environmental sustainability. Every piece recycled or biodegraded is a step closer to a cleaner, greener South Africa, where infrastructure and nature coexist harmoniously with minimal impact.

Energy-efficient Manufacturing – Sustainable production processes

Energy-efficient manufacturing processes are revolutionizing how we approach sustainable infrastructure development. When it comes to trunking 50mm x 25mm, choosing products crafted with eco-friendly principles makes a tangible difference. Modern production methods prioritize reducing carbon footprints by utilizing recycled metals like aluminum and steel, which can be reprocessed endlessly. This not only conserves natural resources but also minimizes energy consumption during manufacturing.

Furthermore, some manufacturers adopt sustainable production practices by integrating biodegradable plastics into their trunking 50mm x 25mm offerings. These materials break down harmlessly within a few years, aligning with global efforts to combat plastic pollution. Such initiatives demonstrate a commitment to environmental responsibility, ensuring that electrical infrastructure does not come at the expense of South Africa’s fragile ecosystems.

- Implementing eco-conscious supply chain management.

- Utilizing renewable energy sources in manufacturing facilities.

- Designing for recyclability and minimal waste during production.

By supporting companies that prioritize sustainable manufacturing, electrical professionals and consumers alike contribute to a greener future. Every piece of trunking 50mm x 25mm produced with energy-efficient methods helps reduce the overall environmental impact, fostering a resilient, eco-friendly infrastructure for generations to come. Embracing these sustainable practices is more than a trend; it’s a vital step toward preserving South Africa’s natural beauty and resources amidst rapid urbanization.

0 Comments