Understanding Trunking Cutting Tools

What is a Trunking Cutting Tool?

In the intricate dance of electrical installation and data management, precision becomes paramount. Enter the realm of the trunking cutting tool—an artisan’s instrument, designed to carve through the rigid exteriors of trunking with effortless grace. This specialized tool is more than a mere implement; it is a gateway to seamless wiring, transforming chaos into order with a single, clean cut.

Understanding the importance of a trunking cutting tool reveals its vital role in ensuring safety and efficiency. Unlike generic cutters, these tools are crafted with durability and finesse, capable of slicing through tough plastic or metal trunking without damaging the internal components. Their sharp blades and ergonomic design allow for swift, accurate cuts, reducing installation time and minimizing waste.

- Precision blades engineered for clean, burr-free edges

- Ergonomic handles for prolonged use without fatigue

- Durability to withstand the rigors of professional use

In a landscape where electrical systems grow increasingly complex, the trunking cutting tool stands as a silent guardian—ensuring every conduit and cable finds its rightful place, unblemished and ready for connection. This tool isn’t just a necessity; it’s an artist’s scalpel in the hands of a skilled technician, shaping the future of efficient electrical infrastructure in South Africa and beyond.

Types of Trunking Cutting Tools

When it comes to wielding a trunking cutting tool, variety is the spice of life—and the key to perfection. Not all cutting tools are created equal, especially when precision and durability are on the line. In the world of electrical installations, understanding the different types of trunking cutting tools can be the difference between a neat, professional finish and a chaotic mess of jagged edges.

For the seasoned technician, the choice often boils down to a few trusty options. There are manual cutters, which offer simplicity and control—ideal for small jobs or tight spaces. Then, heavy-duty power tools come into play, making quick work of thick, industrial trunking. Some models even feature adjustable blades, allowing for customized cuts that fit snugly around cables and conduits. To illustrate, here’s a quick rundown of the common types:

- Manual snips with ergonomic handles

- Electric or cordless cutters for speed and efficiency

- Heavy-duty hydraulic cutters for industrial applications

Choosing the right trunking cutting tool is essential because it directly impacts safety, accuracy, and the overall quality of your electrical infrastructure. Whether you’re a South African electrician or a DIY enthusiast, investing in the appropriate tool ensures your work is not only compliant but also a cut above the rest. Because, let’s face it, no one wants a jagged edge in their trunking—unless they’re aiming for abstract art!

Materials and Construction

In the realm of trunking cutting tools, material selection and construction are the unsung heroes ensuring longevity and precision. A well-crafted trunking cutting tool isn’t just about sharp blades; it’s about robustness, ergonomics, and the ability to withstand the rigours of daily use. The materials used in manufacturing these tools can significantly influence their performance, especially when dealing with the tough plastics and metals common in electrical trunking.

Most high-quality trunking cutting tools are constructed from hardened steel or alloyed metals, which provide a perfect balance of durability and ease of use. These materials resist corrosion, a crucial feature for the often humid environments encountered in South Africa’s diverse climates. Additionally, some models feature ergonomic handles made from composite materials or rubber, offering a comfortable grip and reducing fatigue during extended use.

Understanding the construction of your trunking cutting tool can make all the difference. For instance, tools with precision-ground blades and reinforced joints tend to offer cleaner cuts and longer service life. Whether you opt for a manual snip or a powered cutter, the material quality directly correlates with performance, safety, and the ultimate finish of your electrical installation.

Key Features and Benefits

Precision and Accuracy

In the shadowed corridors of electrical installation, precision is not merely a virtue—it is the very essence of safety and efficiency. The trunking cutting tool emerges as a silent sentinel, wielded with unwavering accuracy to carve through the darkness of tangled cables and stubborn enclosures. Its razor-sharp blade and meticulously calibrated mechanisms ensure each cut is true, transforming chaos into order with surgical finesse.

What sets a high-quality trunking cutting tool apart is its ability to deliver consistent, clean cuts—an essential trait when working with intricate electrical systems. The benefits are profound: less material wastage, reduced risk of damage, and an overall enhancement in the craftsmanship of every project. For those who demand mastery over their craft, the precision and accuracy of a trunking cutting tool are not just advantages—they are prerequisites.

In essence, this tool embodies the dark elegance of meticulous engineering. It offers:

- Unparalleled sharpness for smooth, precise cuts

- Robust construction for enduring performance in rigorous environments

- Ergonomic design that ensures stability and control even during extended use

With a trunking cutting tool in hand, the shadows of uncertainty lift, revealing a realm where every cut is a testament to mastery and meticulousness—an ode to the craftsmanship that underpins every luminous wire and safe connection.

Ease of Use

In the shadowed corridors of electrical craftsmanship, the ease of use of a trunking cutting tool can be the difference between chaos and clarity. A tool that feels like an extension of your hand, seamlessly blending power with finesse, elevates the entire process. Its ergonomic design is crafted for precision, allowing electricians in South Africa to wield it with confidence, even in tight, unforgiving spaces. No longer must one wrestle with cumbersome equipment or struggle for control—this tool offers a symphony of balance and stability.

What truly sets a high-quality trunking cutting tool apart is its intuitive operation. Even after hours of use, the smooth action remains effortless, reducing fatigue and ensuring each cut is as clean as the first. For those who demand mastery, the design incorporates features like easy blade replacement and safety mechanisms that prevent accidental injury, making the tool both reliable and user-friendly.

To encapsulate its core advantages, consider these key features:

- Lightweight yet robust construction that endures the rigors of demanding environments

- Ergonomic handles designed to reduce strain during extended use

- Precision blades that deliver crisp, accurate cuts every time

In the realm of electrical installation, where every cut must be flawless, the trunking cutting tool stands as a beacon of reliability—an artisan’s instrument that transforms the dark, tangled web of cables into a symphony of order, safety, and efficiency.

Durability and Longevity

Durability and longevity are the bedrock upon which a truly exceptional trunking cutting tool is built. In the unpredictable environments faced by South African electricians—whether navigating tight urban spaces or rugged rural sites—robust construction ensures that this essential tool can withstand the test of time. Steel blades, reinforced handles, and resilient materials make each cut not just precise but also reliable over countless projects.

Investing in a high-quality trunking cutting tool means embracing a level of craftsmanship that prioritizes endurance. Its design incorporates features that resist wear and tear, reducing the need for frequent replacements and minimizing downtime. This commitment to longevity translates into significant cost savings and unwavering confidence during critical installations.

For added assurance, many top-tier trunking cutting tools boast:

- Corrosion-resistant coatings that combat the humid South African climate

- Heavy-duty blades engineered for repeated use without dulling

- Shock-absorbing handles that mitigate strain during prolonged work sessions

Such attributes elevate the trunking cutting tool from a mere instrument to a steadfast partner—one that embodies resilience, precision, and enduring performance in every cut. It’s this blend of toughness and meticulous engineering that transforms routine electrical installations into works of craftsmanship, ensuring safety and efficiency are never compromised.

Safety Features

In the realm of electrical craftsmanship, safety is the silent guardian—an unwavering promise woven into every feature of the trunking cutting tool. This precision instrument is more than just a blade and handle; it’s a shield designed to protect and empower the electrician in every cut. With safety features that prioritize user confidence, the trunking cutting tool transforms routine installations into a harmonious dance of skill and security.

One of the most vital safety attributes is the incorporation of lock mechanisms that prevent accidental engagement, ensuring the blade remains steadfast during handling. Shock-absorbing handles act as a buffer against fatigue and unintended slips, absorbing the impact of prolonged work sessions. Many models also feature blade guards that retract smoothly, exposing the cutting edge only when necessary, reducing the risk of injury during storage or transport.

For enhanced safety, some trunking cutting tools include:

- Ergonomic, anti-slip grips for secure handling

- Corrosion-resistant coatings to prevent rust and maintain integrity over time

- Shock-absorbing components that lessen the strain on the user’s hands and arms

Each of these features contributes to a seamless union of safety and performance, transforming the trunking cutting tool into a dependable partner on every project. In environments where precision and protection are paramount, such safety features are not just an added bonus—they are an absolute necessity, ensuring that every cut is both accurate and safe in the bustling, unpredictable landscapes of South Africa.

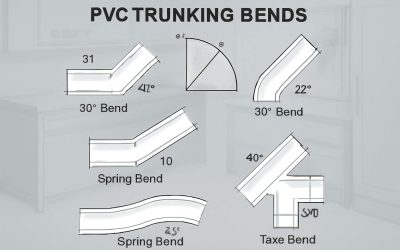

Compatibility with Different Trunking Materials

The true test of a trunking cutting tool lies in its ability to seamlessly adapt to various trunking materials—each demanding a different approach, a different finesse. In the bustling landscapes of South Africa’s electrical industry, versatility isn’t just an advantage; it’s a necessity. A well-designed trunking cutting tool should effortlessly handle PVC, metal, or composite trunking, ensuring precision without compromising safety or efficiency. This adaptability transforms a simple device into a vital extension of the electrician’s skill set, allowing for smooth, accurate cuts regardless of the material’s complexity.

To truly appreciate the compatibility of a trunking cutting tool, consider its cutting edges and adjustable features. A model that features interchangeable blades or adjustable depths can dramatically improve workflow, reducing the need for multiple tools. This flexibility not only saves time but also minimizes errors—an essential factor when working in unpredictable environments where every second counts. The right trunking cutting tool, capable of navigating different materials with ease, becomes an indispensable asset in the electrician’s arsenal, elevating craftsmanship to new heights.

Types of Trunking Cutting Tools Available

Manual Trunking Cutters

Manual trunking cutters are the unsung heroes of electrical installation projects, quietly transforming the cumbersome task of trunking cutting into a precise art. Unlike their powered counterparts, these tools offer the finesse and control that seasoned electricians prize—imagine wielding a scalpel in a world of chainsaws. With the right trunking cutting tool, clean, accurate cuts become second nature, reducing waste and the need for rework. These tools are particularly favored in settings where finesse and safety are paramount, such as in tight spaces or delicate environments.

Among the most popular options are hand-held, lever-operated cutters and compact snips. They’re designed to cut through various materials like PVC, metal, and composite trunking, making them versatile and indispensable. For those who prefer a systematic approach, some professionals opt for an ordered list of essential features:

- Ergonomic handles for prolonged use without fatigue

- Sharp, durable blades that stay keen over time

- Adjustable settings for different trunking thicknesses

In essence, a well-chosen trunking cutting tool can elevate your work from good to exceptional, all while ensuring safety and precision—because in the world of trunking, the devil truly is in the details.

Electric and Cordless Trunking Cutters

Electric and cordless trunking cutters have revolutionised the way professionals approach trunking installation, offering unmatched speed and efficiency. These power tools are perfect for tackling larger projects where manual effort might slow down progress. With the latest advancements, cordless models provide freedom of movement, eliminating the hassle of cords and ensuring seamless access in tight or awkward spaces. The convenience of battery-powered trunking cutting tools means you can work longer without fatigue, while maintaining precision and control.

Among the most sought-after options are versatile, high-torque cutters designed to slice through PVC, metal, and composite trunking with ease. Their compact design allows for easy maneuvering, even in confined spaces. Some models feature adjustable cutting depth and built-in safety mechanisms, making them ideal for both seasoned electricians and those new to trunking installation. Whether you prefer the robust power of electric trunking cutters or the mobility of cordless alternatives, choosing the right tool can significantly elevate your craftsmanship in electrical projects.

Bi-Metal and Carbide Blades

Within the shadowed corridors of electrical craftsmanship, the choice of a trunking cutting tool can mean the difference between mastery and chaos. When precision meets power, the right blades become your silent allies in shaping the conduit of progress. Two formidable contenders stand at the forefront: bi-metal and carbide blades, each whispering promises of durability and razor-sharp efficiency.

Bi-metal blades are revered for their flexibility and resilience, capable of slicing through PVC and softer metals with a graceful yet deadly precision. Their layered composition grants a surprising longevity, resisting wear even under relentless use. Conversely, carbide blades are the stuff of legend—fortified with a crystalline edge that can conquer the toughest trunking materials, from hardened steel to composite substrates. They embody the ultimate in cutting endurance, turning seemingly impenetrable barriers into mere slivers of possibility.

- Bi-metal blades excel in versatility, offering a smoother cut and easier handling in routine installations.

- Carbide blades, however, dominate when facing the most resilient trunking materials, ensuring minimal downtime and maximum efficiency.

In the realm of trunking cutting tools, understanding the subtle differences between these blades unlocks a new level of craftsmanship. Whether you prefer the adaptable grace of bi-metal or the unyielding strength of carbide, selecting the right blade ensures your work remains impeccable—no matter how dark or demanding the project becomes.

Specialized Cutting Instruments for Different Trunking Types

In the intricate dance of electrical installation, selecting the right trunking cutting tool can elevate your craftsmanship from mere competence to artistry. Different trunking types demand specialized cutting instruments that match their unique properties. For example, rigid metal trunking often requires heavy-duty, high-precision tools, while flexible PVC trunking benefits from more versatile options. Recognizing these distinctions ensures efficiency and safety on site, avoiding unnecessary delays and material wastage.

For each trunking type, there are tailored tools designed to optimize performance. Manual trunking cutters excel with lightweight or softer materials, offering precision without sacrificing control. Meanwhile, electric and cordless trunking cutters provide the power needed for more resilient materials, reducing fatigue and speeding up the workflow. Sometimes, a combination of these tools, aligned with specific trunking materials, becomes essential for maintaining high standards of safety and quality.

- Manual trunking cutters for delicate or thin-walled trunking

- Electric trunking cutters for hardened steel or thick PVC

- Cordless options for flexible, on-the-go cutting needs

Understanding the nuances of these specialized cutting instruments ensures that every cut is flawless, every installation seamless. The right choice of trunking cutting tool transforms a challenging task into a straightforward process, especially when faced with the diverse materials encountered in South African electrical projects. Whether you’re working with lightweight conduit or tackling industrial-grade trunking, having the appropriate tool at hand is nothing short of essential.

How to Choose the Right Trunking Cutting Tool

Factors to Consider

Choosing the right trunking cutting tool requires more than just selecting the first option that catches your eye. With the vast array of models available, understanding key factors can make all the difference in ensuring a clean, efficient cut every time.

One of the most crucial considerations is the *blade quality*. High-quality blades, such as bi-metal or carbide, offer enhanced durability and precision, especially when working with tougher materials. Additionally, the *ergonomics of the handle* can significantly impact user comfort during extended use, reducing fatigue and increasing safety.

For those tackling different trunking materials, compatibility becomes paramount. A *trunking cutting tool* that adapts seamlessly to various materials—from PVC to metal—saves time and money.

Finally, consider the *power source*. Electric and cordless models offer unmatched convenience and portability, perfect for on-site projects. Balancing these factors will help you select a trunking cutting tool that stands the test of time and meets your specific needs.

Brand and Quality

When it comes to selecting a *trunking cutting tool*, brand reputation and quality should never be overlooked. In a landscape flooded with options, choosing a trusted manufacturer can mean the difference between a clean cut and costly mishaps. Brands with a proven track record often incorporate advanced manufacturing standards, ensuring each *trunking cutting tool* is built for precision and durability. It’s worth investing in equipment that stands the test of time, especially when working on critical electrical or communication installations.

Beyond brand recognition, evaluating the *quality* of the *trunking cutting tool* itself is essential. Look for tools that feature robust construction, such as hardened steel components or reinforced handles, which can withstand rigorous use. An often overlooked aspect is the availability of replacement blades or parts—this ensures your investment remains functional long after the initial purchase. Remember, a high-quality *trunking cutting tool* not only improves safety but also enhances efficiency on every project site.

Cost vs. Value

When navigating the labyrinth of options for a *trunking cutting tool*, the age-old dilemma of cost versus value rears its head. It’s tempting to seize the cheapest deal, but in the world of electrical and communication installations, a seemingly modest saving can come at a hefty price—think compromised safety, uneven cuts, or premature tool failure. Instead, consider the true value a well-chosen *trunking cutting tool* offers—precision, longevity, and peace of mind. As with most investments, it’s not just about the initial outlay but the long-term performance.

To make an informed choice, evaluate the *trunking cutting tool* not solely on price but on how well it aligns with your project demands. Look for features such as ergonomic design, sturdy construction, and compatibility with the trunking materials you work with daily. Sometimes, a slightly higher investment in a reputable brand ensures you’re equipped with a tool that performs flawlessly over time—saving you both money and frustration in the long run. Remember, a *trunking cutting tool* that offers excellent value can elevate your craftsmanship and streamline your workflow, proving that quality often pays for itself in the end.

Maintenance and Safety Tips

Proper Tool Maintenance

Proper maintenance of your trunking cutting tool is essential to ensure safety and extend its lifespan. Regularly inspecting blades for signs of wear or damage can prevent accidents and maintain cutting precision. A dull or chipped blade not only compromises the quality of the cut but also increases the risk of injury. Always clean your trunking cutting tool after use, removing dirt, dust, and debris that can hinder performance. Lubricating moving parts periodically reduces friction and prevents rust, keeping the tool operating smoothly.

To keep your trunking cutting tool in top shape, consider following a few simple safety and maintenance steps. For instance, storing the tool in a dry, secure location will protect it from moisture and accidental damage. Additionally, using the correct blade for specific trunking materials ensures efficiency and safety. For those working with different types of trunking, having a variety of blades—such as bi-metal or carbide—on hand can make all the difference. Remember, a well-maintained trunking cutting tool is not just about prolonging its life; it’s about safeguarding your hands and ensuring every cut is precise and safe.

Handling and Safety Precautions

Handling a trunking cutting tool safely isn’t just about following rules; it’s about respecting the craft and understanding the risks associated with improper use. A moment’s lapse can lead to injuries or compromised cuts, which is why safety should always be front and centre when working with this essential equipment. Proper handling techniques—such as maintaining a firm grip and ensuring a stable workspace—can significantly reduce the likelihood of accidents.

In addition to careful handling, routine safety precautions are vital. Always wear appropriate personal protective equipment (PPE), including gloves and eye protection, to shield yourself from sparks or debris. When changing blades or performing maintenance, ensure the trunking cutting tool is unplugged or disconnected from power sources to prevent accidental activation.

To further enhance safety and efficiency, consider implementing these simple steps:

- Store your trunking cutting tool in a dry, secure location away from moisture and unauthorized use.

- Use the correct blade for the specific trunking material to prevent damage and ensure precision.

- Regularly inspect blades for signs of wear or damage, replacing them when necessary to maintain optimal performance.

By adhering to these handling and safety precautions, professionals can prolong the lifespan of their trunking cutting tool while safeguarding themselves and their colleagues. Remember, a well-maintained tool combined with cautious operation transforms a routine task into an exercise in craftsmanship, precision, and safety!

Storage Guidelines

When it comes to maintaining peak performance and ensuring safety, proper storage and diligent maintenance of your trunking cutting tool cannot be overstated. A neglected tool not only risks diminished accuracy but also jeopardizes safety—the last thing any professional needs on a demanding job site. Regularly inspecting blades for signs of wear, such as dullness or chips, helps prevent uneven cuts and reduces the likelihood of accidents. Maintaining your trunking cutting tool with a light coating of oil after use wards off corrosion, extending its lifespan and ensuring it remains ready for the next precise cut.

Storage plays an equally crucial role. A dry, secure environment shields your trunking cutting tool from moisture, which can lead to rust and degradation of critical components. Consider investing in a dedicated toolbox or storage case designed to keep blades and handles protected from dust and accidental damage. For added safety, store blades separately and ensure the tool is turned off or disconnected from power sources when not in use.

- Store in a dry, secure location away from moisture and unauthorized access.

- Use protective covers or cases to prevent accidental contact with blades.

- Keep blades separate from the main body to avoid dulling or damage.

By integrating these storage guidelines and routine maintenance practices into your workflow, you not only preserve the integrity of your trunking cutting tool but also uphold a safe, efficient working environment. A meticulously maintained tool is a testament to professionalism and craftsmanship—transforming a simple task into an exercise in precision and safety that endures over time.

Application Areas and Use Cases

Electrical Installations

Electrical installations in South Africa demand precision and efficiency, making the right trunking cutting tool essential for professional electricians. These tools are indispensable when it comes to creating neat, safe, and compliant cable management systems in commercial and residential settings. From installing trunking along walls in office buildings to retrofitting existing electrical panels, a high-quality trunking cutting tool ensures clean cuts and smooth edges, reducing installation time significantly.

Application areas for a trunking cutting tool are diverse, spanning from industrial electrical setups to intricate household wiring. Use cases often involve cutting trunking to custom lengths, fitting junctions, or creating access points for wiring. In larger projects, electricians rely on these tools to handle different trunking materials—be it PVC, metal, or composite—each requiring specific cutting techniques. The versatility of a trunking cutting tool makes it a vital component for maintaining a seamless workflow in any electrical installation project.

Networking and Data Cabling

In the realm of networking and data cabling, precision is paramount. Whether installing a new data center or upgrading an existing office infrastructure, a reliable trunking cutting tool becomes an indispensable ally for electricians and cabling specialists alike. These tools facilitate clean, accurate cuts in trunking systems, ensuring seamless cable runs that are both aesthetically pleasing and compliant with industry standards.

Application areas for a trunking cutting tool extend beyond mere installation; they encompass intricate tasks such as creating access points for data outlets or fitting junctions in tight spaces. For instance, when retrofitting a commercial building in Johannesburg or Cape Town, professionals often need to customize trunking lengths to fit specific architectural features. A high-quality trunking cutting tool allows for these modifications without compromising the structural integrity of the trunking material, whether PVC, metal, or composite.

Use cases include:

- Cutting trunking to precise lengths for wall-mounted data distribution systems.

- Fitting junctions or elbows to navigate complex wiring routes through confined spaces.

- Creating access points for network connections in retrofit projects or new builds.

In larger projects, especially where multiple trunking materials are involved, the versatility of a trunking cutting tool shines. It adapts effortlessly to different materials, providing smooth, clean cuts that reduce installation time and elevate safety standards. From cutting through sturdy metal trunking in industrial settings to delicate PVC in residential wiring, the right tool ensures efficiency and quality every step of the way.

Commercial and Industrial Projects

In the shadowed corridors of commercial and industrial projects across South Africa, the humble trunking cutting tool emerges as an unsung hero—an instrument of precision in a realm where every millimeter matters. When navigating the labyrinth of wiring and data pathways, the ability to customize trunking with seamless, clean cuts can mean the difference between chaos and order. These tools are essential for creating access points, fitting junctions, or tailoring lengths to architectural intricacies that challenge even the most seasoned electricians.

From retrofitting sprawling office complexes in Johannesburg to industrial facilities in Durban, the application areas for a trunking cutting tool are vast and varied. Professionals often find themselves needing to adapt trunking materials—PVC, metal, or composite—to fit unique spaces. Whether slicing through sturdy metal trunking or delicately trimming PVC, a reliable trunking cutting tool ensures that each cut is precise, reducing installation time and elevating safety standards.

- Creating custom lengths for wall-mounted data systems

- Fitting junctions or elbows to navigate complex wiring routes

- Designing access points for network connections during retrofit projects

In larger projects, the versatility of a trunking cutting tool truly shines. It effortlessly transitions between different materials, providing smooth, accurate cuts that uphold structural integrity and aesthetic appeal. As the darkness of night descends, these tools become the silent guardians of order, transforming chaotic wiring into a symphony of precision craftsmanship—proof that in the shadows, mastery persists.

Home Renovations

Home renovations often present a unique set of challenges, especially when it comes to integrating new wiring and data systems seamlessly into existing structures. A quality trunking cutting tool becomes invaluable in these scenarios, allowing for precise modifications that maintain both functionality and aesthetics. Whether you’re tailoring trunking lengths to fit tight spaces or creating custom access points, the ability to cut cleanly through various materials is critical.

In residential projects, the application of a trunking cutting tool extends beyond mere cutting. It enables homeowners and professionals alike to design a wiring layout that is both discreet and durable. For instance, fitting junctions or elbows to navigate around corners or structural features can be achieved with minimal fuss using the right tool. This not only simplifies installation but also enhances safety and compliance with local electrical standards.

For those tackling intricate home upgrades, a trunking cutting tool offers versatility that is hard to match. From cutting through PVC trunking to working with lightweight metal variants, a reliable tool ensures each cut is smooth and precise, saving time and reducing material waste. The result is a polished finish that aligns with the high standards expected in modern South African homes, where every detail matters.

Where to Buy Trunking Cutting Tools

Online Retailers

Finding a reliable source to purchase a trunking cutting tool online can make all the difference in your electrical or networking project. In South Africa, the convenience of browsing through reputable online retailers means you can access high-quality tools without leaving the comfort of your workspace. Many local and international stores offer a wide selection, ensuring you find the perfect fit for your specific needs.

When searching for where to buy a trunking cutting tool online, consider retailers that prioritize product authenticity and customer service. Platforms like dedicated hardware suppliers or specialized electrical tool stores often feature detailed descriptions and user reviews, helping you make an informed decision. Whether you’re undertaking a small home renovation or a large industrial installation, selecting the right retailer ensures durability and performance in your trunking cutting tool.

To streamline your shopping experience, here are some trusted online retailers in South Africa where you can find a trunking cutting tool:

- Building Material Suppliers with an online storefront

- Specialized electrical tool stores with comprehensive product ranges

- Major e-commerce platforms offering competitive prices and fast shipping

Always verify that the retailer provides warranty coverage and after-sales support—these factors are vital when investing in a trunking cutting tool that will serve you reliably for years to come.

Specialist Tool Stores

For those seeking precision and reliability in their electrical or networking projects, specialized tool stores are often the best destination to find a quality trunking cutting tool. These stores focus exclusively on electrical tools and equipment, ensuring that every product meets high standards of durability and performance. Visiting a dedicated electrical tool store offers the advantage of expert advice and access to a broader selection of trunking cutting tools tailored for different trunking materials and installation needs.

Many of these stores stock an array of manual and electric options, from robust manual trunking cutters to cordless, battery-powered devices. Their knowledgeable staff can guide you toward the best choice based on your project scope and budget. Additionally, specialized stores often carry the latest in cutting technology, such as bi-metal or carbide blades, which can significantly enhance cutting precision and longevity. For a seamless shopping experience, consider stores that provide detailed product descriptions and customer reviews—these features help ensure you select a trunking cutting tool suited to your specific requirements.

Wholesale Suppliers

When sourcing a trunking cutting tool wholesale, discerning professionals know that the right supplier can elevate their project from mundane to masterful. South Africa’s electrical and networking sectors are booming, and with that growth comes a demand for reliable, high-quality tools at competitive prices. Opting for wholesale suppliers ensures you’re not only getting the best deal but also accessing an extensive inventory that caters to diverse needs.

Many reputable wholesale suppliers operate online, simplifying the procurement process with detailed product descriptions and robust customer reviews. These platforms often feature an array of trunking cutting tools, from manual cutters designed for precision to electric models that handle tougher materials with ease. For those who prefer the tactile reassurance of inspecting before buying, local distributors and trade wholesalers provide the perfect solution.

- Choose suppliers with a proven reputation for quality and durability.

- Ensure they stock a variety of trunking cutting tools suitable for different trunking sizes and materials.

- Look for vendors offering bulk discounts or loyalty programs to maximize value.

In South Africa, the best wholesale suppliers understand the importance of safety and compliance, ensuring each trunking cutting tool meets industry standards. Whether outfitting a large electrical contracting firm or a small installation team, sourcing from trusted wholesalers guarantees you secure reliable tools that won’t let you down mid-project. After all, a sharp trunking cutting tool is the backbone of a tidy, efficient installation—choose wisely!

Manufacturer Direct Buying Options

Purchasing a trunking cutting tool directly from the manufacturer can be a game-changer for professionals in South Africa. When you buy manufacturer direct, you gain access to the latest models, exclusive features, and often better pricing. Plus, it ensures you receive a product that meets the highest standards of quality and safety. Many trusted brands now offer online ordering options, making it easy to secure a trunking cutting tool without the hassle of middlemen.

For those who prefer a hands-on approach, visiting the manufacturer’s local distributors or authorized dealerships is an excellent choice. These outlets often stock a comprehensive range of trunking cutting tools, from manual cutters to electric models, ensuring compatibility with different trunking sizes and materials. Whether you’re outfitting a large electrical contracting firm or a small installation team, buying directly from the manufacturer guarantees you get a durable, reliable tool tailored to your specific needs.

- Check for official manufacturer websites or authorized dealer listings.

- Verify product authenticity and compliance with industry standards.

- Compare prices and warranty options directly through the manufacturer.

In South Africa, making a direct purchase from a trusted manufacturer provides peace of mind. It ensures you’re investing in a trunking cutting tool that stands up to rigorous use, offers safety features, and delivers precision every time. This approach often results in significant savings over time, especially when considering bulk orders or long-term maintenance support. For professionals committed to excellence, direct buying options are the clear choice for top-tier tools and seamless service.

0 Comments