Steel conduit has been used for years to route electrical wires in buildings and industrial facilities, and it is still one of the most popular ways to conduct a variety of power and data circuits. It is durable, reusable and offers significant protection from physical damage and corrosion.

Metal conduit has a number of different types, including rigid metal conduit (RMC), flexible nonmetallic conduit (ENT) and liquid-tight flexible nonmetallic conduit (LFNC). The conduits are made from different materials and are installed in different ways.

Rigid metal conduit, sometimes referred to as “metal raceway,” is the heaviest of all types of steel conduit and provides the best overall protection for electrical conductors and wiring. It can be used indoors and outdoors, underground, or in concealed locations. It is available in a wide range of sizes and can be fabricated to meet any project requirements.

It has an accurate round section, uniform wall thickness, smooth surface, and continuous welds. It is hot-dip galvanized inside and out for corrosion protection. It is available in a variety of finishes and is UL certified to NFPA 70.

EMT is a thin-wall metal conduit that is typically made of galvanized or aluminum steel. It is often used in corrosive or hazardous environments and is easy to bend with a bending tool. It is available in a wide variety of conduit sizes and can be installed with setscrew, identation or compression-type couplings.

IMC is another type of steel conduit that is commonly used in corrosive and hazardous environments. It is a circular cross-section metal conduit that is unthreaded and normally 10 feet long. It is also available in a variety of finishes and can be installed with setscrew, compression-type couplings and connectors.

Liquid-proof metallic conduits are available in various types, each with a particular combination of fittings. They are particularly suited for machinery, tools and outdoor installations, where it is necessary to be protected from liquids.

They have a plain outer sheath and are available in a variety of conduit sizes and can be supplied with either compression or swivel type couplings, or simple end inserts. They are also available in a variety of fitting styles, and can be supplied with liquid-proof or watertight fittings that meet IP66, IP67, IP68 or IP69k ratings.

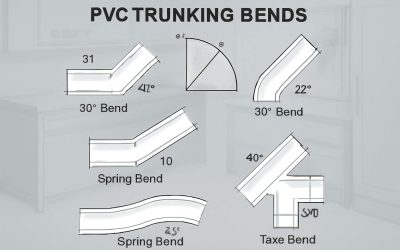

Conduit bodies are designed to provide pulling access in a run of conduit, to allow more bends to be made in a section of conduit, to conserve space where a full size bend radius would be impractical or impossible, or to split a conduit path into multiple directions. They are generally installed in a concrete wall and can be covered with cement.

The conduit body can be made of plastic or metal, and may be painted or plastified. The molded body is usually insulated to prevent moisture from entering the conduit.

Fittings for nonthreaded and threaded conduits are available in a variety of materials, including die-cast zinc, copper-free aluminum or cast iron. The threaded end of the fitting is screwed into a knockout in a junction box or other electrical box, and the nonthreaded end of the fitting has a screw or compression ring that is tightened down onto the inserted conduit.

0 Comments