Understanding Trunking and Its Applications

Definition of Trunking – Explanation of trunking systems and their purpose in electrical and data installations

In the bustling world of electrical and data installations, trunking systems are the unsung heroes, quietly orchestrating order from chaos. Their primary purpose? To safely contain and organize cables, protecting them from damage while ensuring easy access for maintenance and upgrades. Whether in sprawling industrial sites or sleek office complexes, trunking provides a neat, efficient conduit—much like a well-tailored suit that combines style with function.

Understanding trunking is essential for anyone involved in installation projects, as it simplifies complex wiring tasks and enhances safety standards. The trunking bend formula, for example, is a crucial calculation that ensures smooth, precise bends—preventing cable stress and maintaining system integrity. Notably, this formula helps installers determine the correct bend radius, a vital aspect when navigating tight spaces or avoiding structural obstacles.

For those seeking to master the intricacies of trunking design, grasping the trunking bend formula becomes an indispensable skill. It involves a keen understanding of the relationship between bend angles, radius, and the length of the trunking section. Here’s a quick overview of what this entails:

- Calculating the bend radius based on the trunking diameter.

- Applying the trunking bend formula to determine the optimal angle for each bend.

- Ensuring cable pathways are unobstructed and cable stress is minimized, maintaining installation longevity.

In essence, a nuanced grasp of the trunking bend formula elevates an ordinary wiring layout into a masterpiece of engineering precision—an art as much as a science, especially within the dynamic landscapes of South Africa’s infrastructural development.

Common Types of Trunking – Overview of different trunking materials and profiles

Understanding trunking and its applications reveals a fascinating intersection of practicality and engineering finesse. Trunking systems are not merely conduits; they are the silent architects of organized, safe, and efficient wiring infrastructure. In diverse environments—from bustling industrial zones to sleek commercial complexes—their versatility shines through. The selection of common trunking types hinges on factors like durability, flexibility, and aesthetic appeal.

Among the most prevalent are PVC trunking, metal trunking, and flexible trunking profiles. PVC trunking stands out for its affordability and resistance to corrosion, making it a favourite in both domestic and commercial settings. Metal trunking, often galvanized or aluminum, offers enhanced strength and is ideal for heavy-duty applications. Meanwhile, flexible trunking provides adaptability in tight or irregular spaces, allowing installers to navigate complex pathways with ease.

Mastering the intricacies of the trunking bend formula is vital when working with these various types. It enables precise calculations of bend radii and angles, ensuring cables are routed smoothly without undue stress. This understanding transforms a simple installation into a demonstration of engineering artistry, particularly within the unique infrastructural landscape of South Africa. Whether dealing with rigid PVC profiles or flexible conduits, applying the trunking bend formula ensures every bend aligns perfectly, maintaining system integrity and longevity.

Importance of Accurate Bends in Trunking – Why precise bends are essential for system integrity and aesthetics

In the intricate world of electrical installation, precision isn’t just a virtue—it’s a necessity. Every bend in a trunking system must align flawlessly to uphold both system integrity and aesthetic appeal. A miscalculated bend can lead to cable stress, compromised insulation, and even future maintenance nightmares, especially in the complex infrastructural landscape of South Africa.

The trunking bend formula acts as the silent guardian of these delicate pathways. It allows installers to determine the exact bend radius and angle, ensuring cables flow smoothly through every twist and turn. When applied correctly, this formula transforms a potentially chaotic wiring maze into a seamless conduit of safety and efficiency.

- Accurate bends prevent cable damage and reduce the risk of future faults.

- They maintain the professional appearance of the installation, a crucial factor in commercial spaces.

- Properly calculated bends extend the lifespan of the entire electrical system.

In essence, mastering the trunking bend formula isn’t just a technical skill—it’s an art form that guarantees the longevity and reliability of your wiring infrastructure. In South Africa’s diverse environments, from bustling industrial zones to sleek office complexes, this precision ensures every installation stands the test of time.

Basics of Trunking Bends

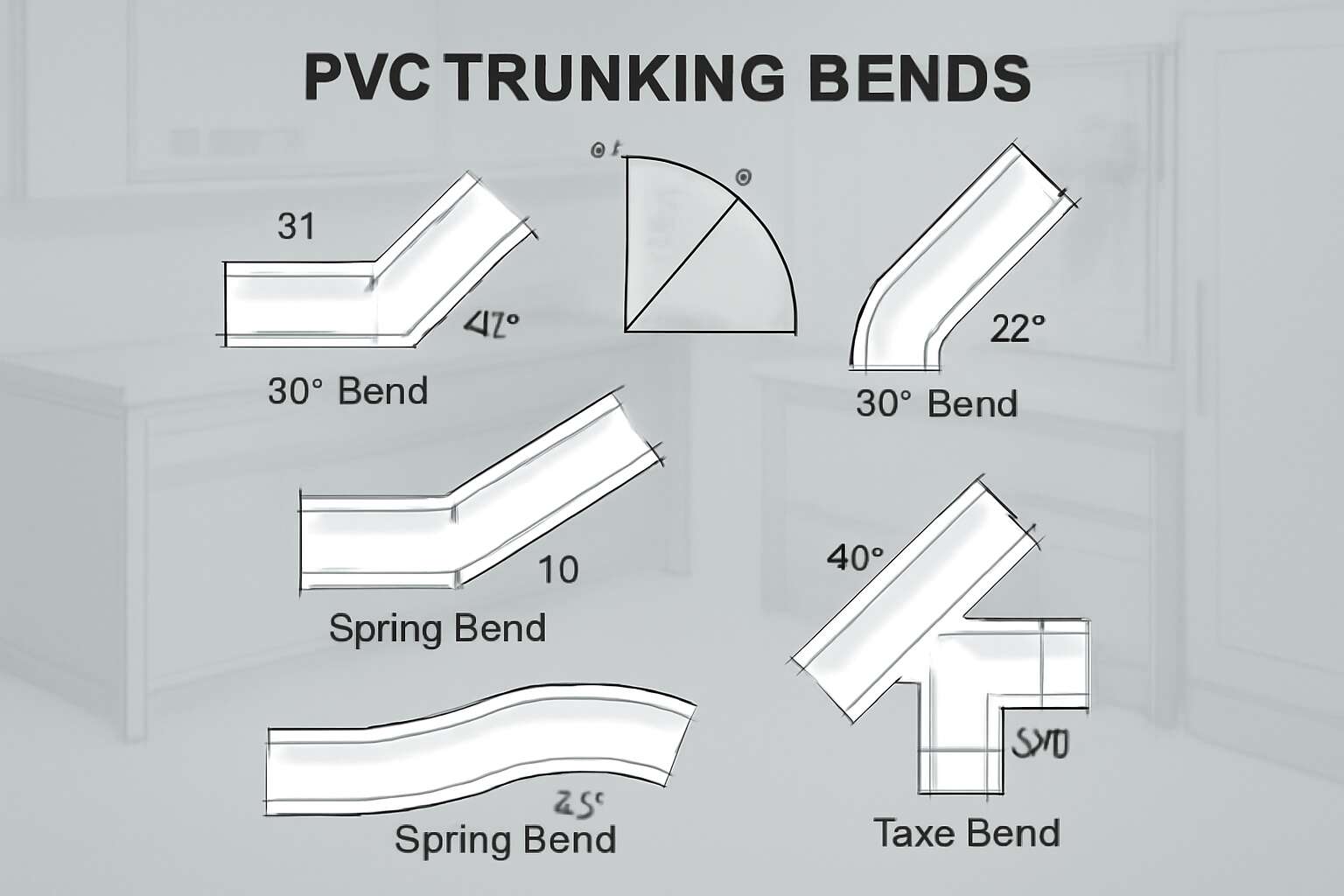

Types of Trunking Bends – Elbow bends, 45-degree bends, 90-degree bends, and custom angles

In the intricate dance of electrical installation, mastering the trunking bend formula is akin to wielding a magician’s wand—transforming raw materials into seamless pathways of connectivity. The art of bending trunking isn’t merely about shaping metal; it’s about precision and intuition, ensuring the flow of energy remains uninterrupted and visually harmonious. When considering the various types of trunking bends, each serves a unique purpose in navigating complex architectural landscapes.

Among the most common are elbow bends, which provide smooth, rounded turns—ideal for tight corners. The 45-degree bends lend themselves to more gradual curves, often used in corridors or to subtly redirect cable runs without sharp deviations. For sharper turns, 90-degree bends are indispensable, creating a right-angled junction that maximizes space efficiency. Custom angles, however, are where the trunking bend formula truly shines, allowing installers to craft bespoke solutions tailored to specific site requirements—an essential aspect in South African electrical projects where versatility often dictates success.

Standard Radius of Bends – Industry norms and their significance

In the realm of electrical installation, understanding the standard radius of trunking bends is crucial for ensuring both safety and functionality. Industry norms have established specific guidelines that dictate the minimum bend radius to prevent damage to cables and maintain system integrity. Typically, the industry standard for trunking bend radius is about 6 times the trunking’s width, though this can vary depending on the cable type and installation environment.

This standard isn’t just a bureaucratic checkbox; it directly impacts the longevity of your electrical system. When applying the trunking bend formula, adhering to these industry norms guarantees that the bends are neither too tight nor too generous, which could compromise the system’s durability. For complex projects, especially in South Africa where diverse architectural styles demand precision, knowing the standard radius of bends offers a reliable starting point for crafting effective trunking systems.

In essence, the trunking bend formula acts as a vital tool—helping installers calculate the correct bend radius, ensuring cables are protected, and the installation remains both efficient and visually harmonious. Whether you’re working with elbow bends or custom angles, applying the right standard radius aligns your work with industry best practices, making your electrical installation a masterpiece of both form and function.

Factors Influencing Bend Radius – Material type, installation environment, and load considerations

In the intricate dance of electrical installation, the materials chosen and the environment in which they reside shape the very essence of a perfect bend. The trunking bend formula isn’t just a mathematical tool; it’s a poetic guide that ensures cable integrity and system longevity. When considering the material type—be it PVC, metal, or flexible trunking—each responds differently to bending stresses, influencing the radius needed for a safe and durable turn.

Installation environment exerts an equally vital influence. Harsh conditions, such as high temperatures or corrosive atmospheres, demand a more cautious approach, often requiring an increased bend radius to prevent material degradation. Load considerations, too, cannot be ignored. Heavy cables or bundles exert pressure that can distort or damage the trunking if bends are too tight, making the application of the trunking bend formula essential for balancing safety with practicality.

- Material properties—rigidity versus flexibility—dictate how sharply a trunking bend can be made without compromising structural integrity.

- Environmental factors—heat, moisture, and exposure—dictate the necessary adjustments to the standard radius.

- The load of cables and accessories—weight and density—must be meticulously considered to prevent undue stress on the system.

Understanding these influencing factors transforms a simple bend into a harmonious junction, ensuring the installation’s resilience. The trunking bend formula becomes a compass—guiding professionals through the labyrinth of variables toward a solution that respects both craftsmanship and safety. It’s this delicate interplay of elements that elevates a basic bend into a testament of engineering finesse, especially in South Africa’s diverse architectural landscape where every bend tells a story of precision and care.

The Trunking Bend Formula: An Overview

Purpose of the Formula – Calculating the correct bend length and radius

Within the intricate realm of electrical and data installations, the trunking bend formula emerges as a guiding star—an essential compass for engineers and electricians alike. This formula acts as the mystical key to unlocking precise bend lengths and radii, ensuring that the conduit maintains its structural integrity and aesthetic harmony. As the backbone of seamless trunking systems, understanding the trunking bend formula allows professionals to craft bends that are both functional and visually pleasing, avoiding the chaos of misaligned pathways.

In essence, the purpose of the trunking bend formula is to provide a mathematical blueprint for calculating the correct bend length and radius, tailored to the specific material and environmental considerations. By applying this formula, a skilled technician can predict how a bend will behave under various conditions, preventing potential failures or aesthetic flaws. Whether working with rigid PVC, flexible metal, or bespoke materials, mastery of the trunking bend formula ensures that every turn in the conduit is a testament to precision and craftsmanship. It’s a secret weapon in the arsenal of anyone committed to excellence in electrical trunking design!

Key Components of the Formula – Understanding the variables involved

The trunking bend formula is a vital tool for ensuring that every bend in electrical and data trunking systems is both precise and reliable. At its core, this formula considers key components that influence how a conduit should be shaped to maintain structural integrity and aesthetic appeal. Understanding these variables is essential for professionals aiming to craft seamless trunking pathways that withstand environmental stresses and meet safety standards.

The primary components of the trunking bend formula include the bend radius, bend angle, and bend length. These variables work together to determine how a conduit should be manipulated to achieve a smooth, accurate turn. For instance, the bend radius is influenced by the material used—rigid PVC, flexible metal, or custom composites—each with its own optimal radius to prevent cracking or deformation.

To better grasp how the formula functions, consider these elements:

- Material properties and flexibility

- Type of bend required—such as 45-degree or 90-degree

- Environmental factors, including load and installation space constraints

By meticulously calculating these variables through the trunking bend formula, engineers and electricians can create bends that are not only functional but also visually harmonious. This mathematical approach ensures every turn in the trunking system aligns perfectly, avoiding costly rework and potential failure points—truly a cornerstone in professional trunking installation.

Relevance of the Formula in Installation – Ensuring precise and efficient trunking bends

In the intricate world of electrical and data installations, precision is not just a virtue—it is an absolute necessity. The trunking bend formula emerges as a silent guardian of quality, guiding professionals in crafting bends that marry function with finesse. This mathematical tool is more than a set of calculations; it is the moral compass that ensures every conduit turn maintains its structural integrity and aesthetic harmony. When executed correctly, these bends become seamless, resilient pathways that withstand environmental stresses and uphold safety standards.

Understanding the relevance of the trunking bend formula in installation reveals its true power. It fosters efficiency, minimizes rework, and prevents failure points that could compromise entire systems. For instance, by accurately calculating the bend radius and angle, electricians can avoid cracking or deformation—common pitfalls when working with different materials like PVC or metal. The formula’s precision allows for the creation of bends that are not only functional but also visually impeccable, embodying the craftsmanship that elevates a simple installation into an art form.

Mathematical Derivation of the Trunking Bend Formula

Basic Geometry Principles – Applying circle arcs and chord calculations

Mathematical derivation of the trunking bend formula is rooted in fundamental geometry principles that transform complex curves into manageable calculations. At its core, this process involves applying circle arcs and chord calculations to accurately determine the bend length and radius, which are crucial for seamless trunking installation. By understanding the relationship between the arc length, radius, and central angle, professionals can precisely predict how a bend will behave under various conditions, ensuring optimal fit and performance.

Key to this derivation is the recognition that a trunking bend is essentially a segment of a circle. Using the basic geometry of circle segments, the formula considers variables such as the bend angle, the radius of the curve, and the length of the chord connecting the start and end points of the bend. Incorporating these elements allows for a comprehensive calculation that accounts for material flexibility and environmental factors. This nuanced approach is what makes the trunking bend formula an indispensable tool in both electrical and data trunking systems.

- The central angle of the bend

- The radius of the bend arc

- The chord length between start and end points

Through this geometrically driven methodology, engineers and installers can confidently determine the most accurate bend dimensions—ultimately ensuring that every turn in the trunking system maintains integrity and aesthetic appeal. The trunking bend formula thus acts as a bridge between raw mathematical concepts and practical, real-world application, elevating installation precision to a new level of excellence.

Common Trunking Bend Formula – Detailed explanation of the formula used in practice

In the realm of electrical and data trunking, the precision of a bend can be the difference between seamless flow and a tangled mess. The mathematical derivation of the trunking bend formula is a fascinating dance between geometry and practicality, transforming complex curves into manageable calculations. This formula hinges on the fundamental principles of circle arcs and chord calculations, providing a reliable blueprint for installers striving for perfection.

At its core, the trunking bend formula considers key variables such as the bend angle, the radius of the curve, and the chord length between start and end points. By understanding how the arc length relates to the radius and central angle, professionals can accurately determine the necessary bend length. This nuanced approach ensures that every turn in the trunking system is both functional and visually appealing, respecting industry standards and environmental constraints.

- The central angle of the bend is pivotal, defining the scope of the curve.

- The radius of the bend influences material flexibility and spatial accommodation.

- The chord length provides a tangible measure connecting the start and end points of the bend.

With these components woven into the trunking bend formula, engineers and installers unlock the ability to craft bends with surgical precision. This mathematical harmony not only elevates installation quality but also guarantees the integrity and longevity of the system. The trunking bend formula, therefore, becomes more than a calculation—it’s a bridge linking abstract geometry with real-world craftsmanship, ensuring every curve in the trunking system is a testament to meticulous engineering.

Examples of Calculation – Sample calculations for different bend angles

The mathematical derivation of the trunking bend formula is a captivating blend of geometry and engineering finesse. By dissecting the relationship between the arc of a circle and its chord, installers gain a powerful tool to craft precise bends. The core principle hinges on understanding how the central angle, radius, and chord length intertwine to produce the perfect curve in a trunking system. This elegant formula transforms complex curves into manageable calculations, enhancing both efficiency and accuracy in installation.

For example, when calculating a 90-degree bend, professionals often use the trunking bend formula to determine the exact length of material needed. Consider a radius of 150mm: the formula guides you to measure an arc length that ensures a smooth, seamless turn. As you adjust the bend angle—say to 45 degrees or a custom angle—the same principles apply, just with modified variables. These calculations are essential for maintaining system integrity and achieving a polished, professional finish.

- Identify the bend angle and radius.

- Calculate the central angle in radians (if necessary).

- Use the trunking bend formula to find the arc length, which is the precise length of trunking material needed for the bend.

Sample calculations vividly demonstrate the versatility of the trunking bend formula. For a 45-degree bend with a 200mm radius, the formula reveals the exact arc length required, ensuring every bend aligns perfectly with the system’s design. Such precision not only saves material but also guarantees the longevity and aesthetic appeal of the installation—making the trunking bend formula an essential compass for every installer in South Africa and beyond!

Practical Applications and Calculation Tips

Using the Formula in Real-World Installations – Step-by-step guidance

In the intricate dance of electrical installations, precision is paramount—especially when navigating the labyrinthine pathways of trunking systems. The trunking bend formula emerges as an indispensable tool, transforming abstract geometry into tangible, reliable bends that uphold both functionality and aesthetics. When applied meticulously, this formula ensures that each bend maintains the integrity of the system, preventing undue stress on materials and minimizing the risk of future faults.

Practically speaking, understanding how to leverage the trunking bend formula in real-world installations offers a significant advantage. For instance, calculating the correct bend radius and length with this formula allows installers to anticipate and accommodate space constraints, reducing costly rework. To streamline complex angles, follow this simple sequence:

- Identify the bend angle—whether it’s a standard 90-degree or a custom curve.

- Measure the available space for the bend radius.

- Apply the trunking bend formula to determine the precise arc length and chord.

This step-by-step approach ensures each bend seamlessly integrates into the overall trunking system, exemplifying the importance of accuracy in every project. Mastery of the formula transforms a challenging task into a precise craft—empowering professionals to craft installations that are as resilient as they are efficient!

Tools and Software – Leveraging CAD and measurement tools

In the realm of electrical installations, precision isn’t just a virtue—it’s a necessity. The trunking bend formula serves as a vital compass, guiding professionals through the complex geometry of trunking bends. Leveraging this formula can dramatically improve accuracy, ensuring each bend is crafted to perfection, reducing the risk of future faults and system stress. Modern tools like CAD software and measurement devices have revolutionized how installers approach these calculations, transforming what was once a painstaking manual process into a seamless, efficient workflow.

By integrating measurement tools such as laser distance meters or digital angle finders, professionals can capture real-world data with extraordinary precision. For those who prefer a digital approach, dedicated CAD programs often feature built-in functions that incorporate the trunking bend formula, allowing for rapid adjustments and refined designs. These tools make it easier to visualize complex angles and ensure the calculated bend radius aligns perfectly with available space, ultimately saving time and materials.

Incorporating the latest calculation software or even mobile apps designed specifically for trunking bend calculations streamlines the entire process. For example, some programs allow you to input the bend angle, material properties, and space constraints, instantly rendering the exact arc length and chord needed. This technological synergy not only accelerates project timelines but also elevates the quality and reliability of trunking systems, making the trunking bend formula an indispensable asset in every installer’s toolkit.

Avoiding Common Mistakes – Tips for accurate measurements and calculations

In the shadowed corridors of electrical craftsmanship, precision is not merely a virtue—it’s a haunting necessity. When navigating the labyrinth of trunking systems, the trunking bend formula acts as a secret incantation, guiding the skilled hand through complex angles and elusive curves. Practical application demands more than mere guesswork; it requires meticulous measurement and unwavering attention to detail. Missteps in calculating bend lengths or radii can lead to system faults or, worse, structural collapse under unseen stress.

To avoid these spectral pitfalls, professionals often rely on a handful of calculation tips. First, always verify the accuracy of your measurements—use laser distance meters or digital angle finders for clarity and certainty. Second, remember that the trunking bend formula hinges on fundamental geometry: understanding the relationship between the arc, radius, and chord is vital. For instance, when working with a 90-degree bend, ensuring the correct radius aligns with the space constraints can mean the difference between a seamless fit and a jarring obstacle. In essence, mastering these calculations transforms a daunting task into an art of precision and elegance.

In the pursuit of perfection, many turn to digital tools—CAD software or dedicated mobile apps—that incorporate the trunking bend formula, making complex calculations almost effortless. These tools often feature intuitive interfaces that allow you to input variables such as bend angle, material properties, and spatial limitations, instantly revealing the exact arc length and chord needed. Such automation not only reduces human error but also breathes life into the darkened chambers of design, illuminating the path toward flawless installation.

Standards and Regulations for Trunking Bends

Industry Standards – BS, IEC, and local codes related to trunking bends

Standards and regulations play a pivotal role in ensuring the safety, reliability, and uniformity of trunking bends across South Africa. Adhering to industry standards such as British Standards (BS), International Electrotechnical Commission (IEC), and local codes guarantees that every bend maintains structural integrity and safety compliance. These standards set the foundation for accurate measurements and proper installation techniques, which are essential in the application of the trunking bend formula.

In particular, the trunking bend formula relies heavily on specific industry norms for bend radius and angle precision. South African electrical installations often draw from these global benchmarks to align with best practices. To facilitate this, some regulations specify:

- Minimum bend radii to prevent cable damage and maintain system flexibility

- Material-specific constraints influencing bend radius

- Design tolerances for custom angles and complex routing

By integrating these standards into the calculation of the trunking bend formula, installers ensure that every bend is both functional and durable, reducing future maintenance issues and upholding safety regulations. This meticulous approach is vital for professionals committed to excellence in electrical and data infrastructure projects.

Safety Considerations – Ensuring compliance for safe installations

In the realm of electrical and data installations, safety is not just a priority—it’s an uncompromising mandate. Industry standards such as BS, IEC, and South African local codes serve as the backbone for ensuring that every trunking bend adheres to rigorous safety and performance benchmarks. These regulations dictate critical parameters like minimum bend radius and angles, which are vital in preventing cable damage and maintaining system flexibility. When calculating with the trunking bend formula, compliance with these standards transforms into a safeguard against potential hazards.

To uphold safety considerations, installers must be acutely aware of specific requirements, including material constraints and design tolerances. A failure to adhere could lead to compromised structural integrity or even system failure. For instance, the trunking bend formula incorporates variables influenced by these standards, guiding professionals to achieve precise bends that conform to safety regulations and industry norms. This meticulous attention to detail ensures installations are durable, reliable, and compliant with all relevant safety codes.

Inspection and Quality Control – Verification processes for bent trunking

Ensuring that trunking bends meet industry standards is vital for safe and reliable electrical and data installations. Verification processes are essential in maintaining quality control, especially when using the trunking bend formula to calculate precise bend radii and angles. These calculations serve as the backbone for ensuring that each bend adheres to strict safety regulations and performance benchmarks.

Inspection of bent trunking involves meticulous checks against established standards such as BS, IEC, and South African local codes. To streamline this process, many professionals rely on a combination of visual assessments and measurement tools, verifying that the actual bends align with the specifications derived from the trunking bend formula. This dual approach helps catch deviations early, preventing costly rework or safety hazards down the line.

- First, measurements are taken to compare the actual bend radius and angle with the calculated values based on the trunking bend formula.

- Next, the material’s flexibility and tolerances are examined to ensure they fall within permissible limits.

- Finally, documentation of each bend’s compliance ensures traceability and accountability during audits or inspections.

Adhering to these verification steps not only guarantees compliance with safety codes but also enhances overall installation quality—an often overlooked but crucial aspect of professional trunking work. In this way, the trunking bend formula becomes more than just a calculation tool; it transforms into a safeguard for safe, durable, and standards-compliant systems.

Expert Tips for Efficient Bending

Material Preparation – Pre-bending considerations

In the realm of electrical artistry, precision is the silent symphony guiding every bend in the trunking system. Before embarking on the intricate dance of bending, seasoned practitioners heed expert tips for efficient material preparation—transforming raw steel or PVC into a seamless conduit of connectivity. Pre-bending considerations act as the blueprint, where understanding the subtleties of material flexibility and environmental factors can make the difference between a flawless installation and a costly misstep.

A key aspect often overlooked is the importance of calculating the exact bend length using the trunking bend formula. This mathematical compass reveals the arc’s true measure, ensuring that each curve aligns perfectly with the intended pathway. Employing this formula, whether for 45-degree or 90-degree bends, helps avoid deformities that compromise both aesthetic appeal and structural integrity.

When preparing for a bend, consider these critical factors:

- The material’s inherent bend radius

- The installation environment’s temperature and load demands

- The necessity of maintaining consistent cable and conduit flow

Mastering the nuances of the trunking bend formula transforms a routine task into an artful craft, where technical precision meets creative intent, forging pathways that are as reliable as they are elegant.

Bending Techniques – Manual vs. mechanical bending methods

When it comes to achieving flawless trunking bends, understanding the difference between manual and mechanical bending methods can save both time and resources. Manual bending offers flexibility and a tactile feel, making it suitable for small-scale or custom projects. However, it demands experience to maintain accuracy, especially when applying the trunking bend formula to determine the correct bend length. Mechanical bending, on the other hand, uses specialized equipment that ensures consistent results, particularly for larger quantities or more complex angles. Both techniques benefit from precise calculations, which is where mastering the trunking bend formula becomes crucial.

For optimal results, consider the specific needs of your installation. Manual methods often involve simple tools like hand bikes and templates, ideal for tight or irregular bends. Conversely, hydraulic or motorized benders are better suited for standard angles like 45° or 90°, where the formula helps confirm the correct bend radius and length. By integrating the trunking bend formula into your workflow, you can prevent deformities and ensure the conduit flows seamlessly. Remember, whether manual or mechanical, accurate measurement is the key to a professional finish that adheres to industry standards.

Minimizing Material Waste – Strategies for resource efficiency

Efficiency in trunking installation isn’t just about speed; it’s about minimizing waste and maximizing precision. Using the trunking bend formula strategically allows professionals to calculate the exact length and radius needed for each bend, drastically reducing material wastage. This meticulous approach not only saves costs but also ensures a cleaner, more professional finish. In environments where resources are tight, applying these calculations becomes even more critical to avoid unnecessary expenses and delays.

One practical tip is to always double-check your measurements against the trunking bend formula before making any cuts. Mistakes at this stage can lead to material discard or rework, which eats into profit margins. For optimal resource efficiency, consider adopting tools or software that incorporate the trunking bend formula—it streamlines the process and minimizes human error. Remember, precision in the initial calculation phase pays off by preventing costly adjustments later on.

- Pre-measure all conduit runs and verify angles to ensure they align with your calculated bend lengths.

- Use templates or jigs based on the trunking bend formula to replicate bends consistently across multiple installations.

- Maintain a meticulous record of your calculations to refine your process over time, especially when working on complex projects.

Ultimately, mastering the trunking bend formula is about working smarter, not harder. It’s the cornerstone of resource-efficient, precise trunking installations—something every professional should aim for in their toolkit. Whether manually calculating or employing advanced bending equipment, understanding and applying this formula helps uphold industry standards while keeping costs in check.

FAQs About Trunking Bend Formula

What is the standard bend radius for trunking? – Typical values and their applications

When working with trunking bend formula, understanding the standard bend radius is crucial for precision and safety. The typical bend radius for trunking varies depending on the material and application, but industry standards generally recommend a radius of at least 1.5 times the trunking’s width. For example, if the trunking is 50mm wide, the bend radius should be around 75mm. This ensures smooth bends that maintain the integrity of the cable or conduit within. In South Africa, adherence to local standards such as SANS 10142 often influences the chosen bend radius, ensuring compliance and durability.

Choosing the correct bend radius isn’t just about safety—it affects the ease of installation and the longevity of the system. Using the trunking bend formula helps technicians calculate the precise length of the bend and minimize material waste, especially in constrained spaces. Whether installing in a commercial setting or a residential project, knowing the industry norms for bend radius ensures a perfect fit every time!

How do I calculate a custom bend angle? – Step-by-step method

In the realm of electrical and data installations, precision is paramount—especially when it comes to bending trunking. The trunking bend formula is a powerful tool that transforms a simple task into an art form, ensuring every curve is both flawless and functional. Calculating a custom bend angle might seem daunting at first glance, but with a clear understanding of the underlying principles, it becomes an intuitive process. Whether you’re working with rigid steel or flexible PVC, knowing how to harness the trunking bend formula can turn complex bends into seamless arcs.

To calculate a custom bend angle, start with the basic geometry involved. First, determine the desired radius of your bend, which should align with industry standards—often at least 1.5 times the trunking width. Next, measure the length of the trunking segment before and after the bend. Using the trunking bend formula, you can derive the exact length of the arc needed for the specific angle you require. The process involves understanding the relationship between the chord, the radius, and the angle itself, which can be simplified through the use of trigonometric functions or dedicated software tools.

For ease, some professionals prefer to follow these steps:

- Identify the desired bend angle (e.g., 45°, 90°, or a custom degree).

- Calculate the radius based on the material and application standards.

- Apply the formula, which generally involves multiplying the radius by the angle in radians to find the length of the arc.

- Adjust measurements based on the specific installation environment to ensure accuracy.

Mastering the trunking bend formula not only guarantees precise bends but also minimizes material waste and installation time—crucial factors in any project. Whether you’re crafting intricate conduit pathways or simply ensuring a smooth transition around corners, understanding how to calculate a custom bend angle with the trunking bend formula elevates your craftsmanship to legendary heights. With a little mathematical magic, every bend becomes a perfect arc — a testament to your skill and attention to detail in the world of trunking installation.

What tools are needed for precise bending? – Recommended equipment and measurement tools

Every master electrician or data installer in South Africa understands that precision in trunking bends is the secret to seamless, professional installations. The trunking bend formula is the enchanted key—transforming a daunting task into a dance of geometry and craftsmanship. To wield this formula effectively, you’ll need the right tools, a keen eye for measurement, and an understanding of the underlying principles that govern perfect bends.

Essential equipment includes a high-quality measuring tape, a flexible ruler, and a protractor for angle estimation. For more advanced precision, a bending jig or mechanical bender designed specifically for trunking can make all the difference. Some professionals also prefer digital tools like CAD software, which allows for meticulous planning and visualization before applying the trunking bend formula in real-world scenarios.

In addition, a sturdy marker or chalk helps to mark your measurements clearly on the trunking material, ensuring accuracy throughout the process. When combined with the right tools and a clear grasp of the formula, these measurement devices enable you to achieve flawless bends—every time. Because at the heart of every skilled installation lies a foundational understanding of the trunking bend formula, turning complex curves into a symphony of perfect arcs!

0 Comments