Understanding Trunking Flange

Definition and Purpose – What is a trunking flange and its role in cable management

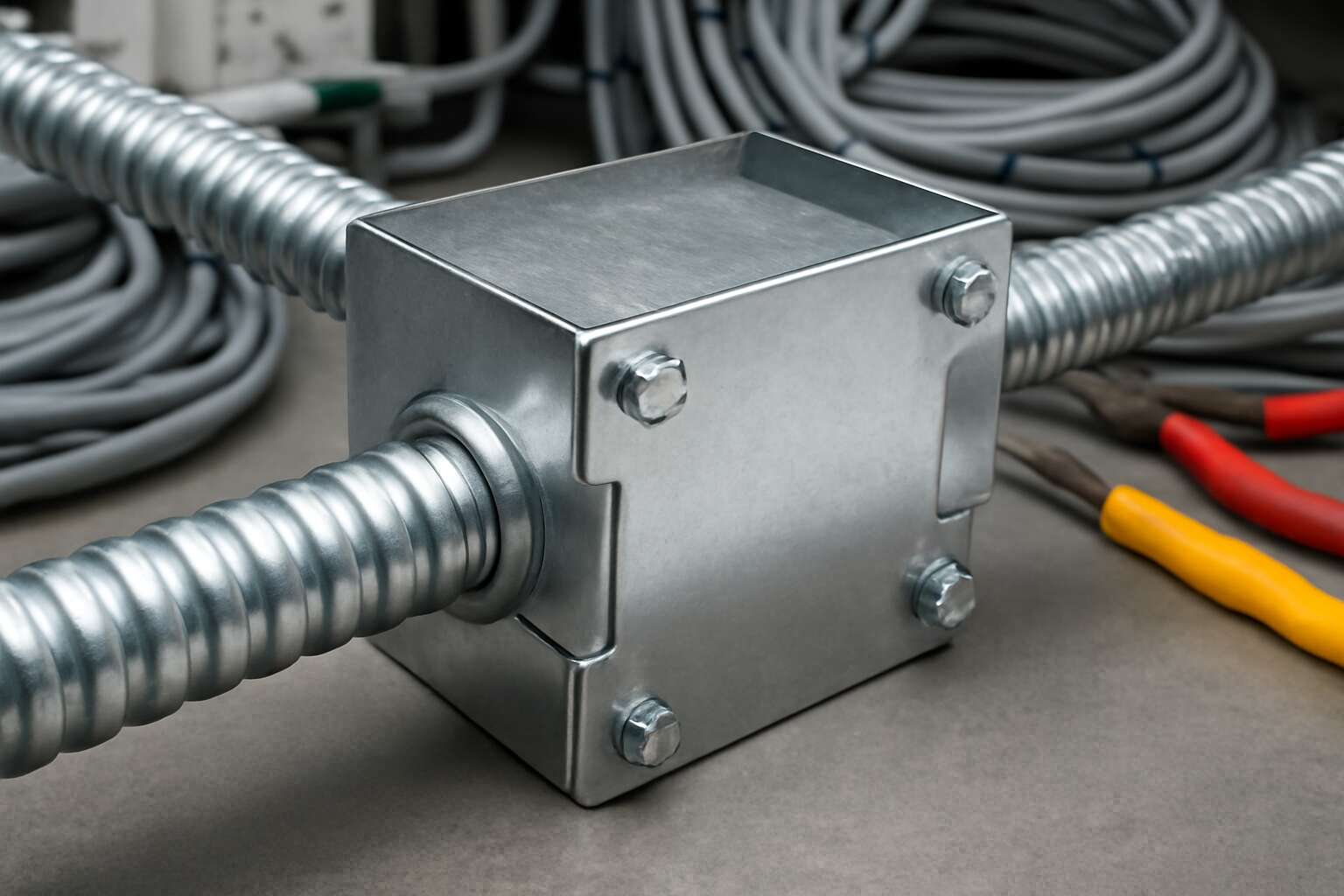

Imagine your neatly organized office or industrial setup—where cables don’t resemble a chaotic spaghetti monster but are instead tucked away with precision and style. That’s the magic of a trunking flange! Essentially, it’s the unsung hero of cable management, providing a clean transition point at the ends of trunking systems. Think of it as a sophisticated gateway that ensures your cables stay secure, protected, and easy to access when needed.

At its core, a trunking flange is designed to seal the open ends of trunking, preventing dust, debris, or curious fingers from disturbing your wiring masterpiece. It’s more than just a tidy finish; it’s a crucial element that maintains the integrity of your cable installation. Whether in a bustling office environment or a sprawling industrial plant, a well-chosen trunking flange can mean the difference between a robust setup and one that’s destined for chaos. So, if you’re serious about cable management, investing in quality trunking flanges isn’t just smart—it’s essential.

Types of Trunking Flanges – Various types and their specific applications

Every masterful cable management system relies on the subtle yet essential role of the trunking flange. But did you know that these components come in a surprising variety, each tailored to specific needs? Understanding the different types of trunking flanges unlocks a new level of precision in your installations. Whether you’re sealing off a junction or creating a seamless transition, choosing the right flange can elevate both safety and aesthetics.

Among the most common are the flat flange, which provides a sleek, flush finish ideal for clean wall installations. Then there’s the angled flange, perfect for corner connections that demand a smooth, unobtrusive transition. For more complex setups, a universal flange offers versatility, accommodating various trunking sizes and shapes. These variations ensure that your cable pathways remain protected and visually appealing, regardless of the environment.

To simplify selection, consider this list of common trunking flange types:

- Flat flange – offers a seamless finish for wall-mounted trunking systems.

- Angled flange – designed for corners and junctions, ensuring a tidy, professional look.

- Universal flange – adaptable to multiple trunking sizes, ideal for dynamic installations.

Each type of trunking flange plays a vital role in maintaining the integrity and safety of your cable management system. With the right choice, your setup not only functions flawlessly but also exudes a sense of meticulous craftsmanship—making every connection a testament to quality and attention to detail.

Materials Used – Common materials for trunking flanges and their benefits

When it comes to selecting the perfect trunking flange, material choice is everything—think of it as the backbone of your cable management masterpiece. In South Africa’s diverse environments, durability and reliability are non-negotiable, which is why common materials like PVC, steel, and aluminum dominate the scene. Each offers unique benefits that can elevate your installation from basic to brilliant.

PVC trunking flanges are the unsung heroes of budget-friendly, corrosion-resistant solutions. They’re lightweight and easy to install, making them ideal for indoor applications where aesthetics matter. Steel, on the other hand, provides unmatched strength and security, perfect for industrial settings with high mechanical stress. Aluminum flanges strike a balance—they’re lightweight yet durable, resisting rust and offering an excellent finish for both indoor and outdoor use.

Here’s a quick rundown of the common materials used in trunking flange manufacturing:

- PVC: corrosion-resistant, cost-effective, and easy to work with.

- Steel: robust, secure, ideal for heavy-duty environments.

- Aluminum: lightweight, rust-resistant, and versatile for various settings.

Choosing the right material for your trunking flange hinges on your specific needs—be it environmental conditions, budget constraints, or aesthetic preferences. Rest assured, the right material can make your cable pathways not only safer but also a visual testament to meticulous craftsmanship.

Key Features and Design Aspects of Trunking Flange

Size and Dimensions – Standard sizes and custom options

In the intricate dance of cable management, the trunking flange emerges as a pivotal performer—an elegant connector that transforms a utilitarian conduit into a symphony of seamless integration. Its key features are crafted with precision, blending durability with finesse, ensuring that every installation stands resilient against the test of time. The size and dimensions of a trunking flange are not mere numbers but a carefully orchestrated balance between functionality and adaptability.

Standard sizes for trunking flanges are designed to fit popular conduit dimensions—typically ranging from 20mm to 150mm in diameter—ensuring compatibility across diverse applications. Yet, the true marvel lies in the custom options available; bespoke trunking flanges can be engineered to meet the unique demands of any project, offering tailored solutions that elevate electrical installation standards. Whether working within tight spaces or expansive industrial settings, the right flange size ensures a secure, leak-proof connection that upholds safety and efficiency.

- Versatility in dimensions to suit various trunking systems

- Custom fabrication options for specialised requirements

- Robust construction designed to withstand South Africa’s diverse environmental conditions

Installation Features – Design elements that facilitate easy installation

In the realm of efficient cable management, the design of a trunking flange is often overlooked—yet it is fundamental to seamless installation and long-term reliability. Key features such as precision-engineered fastening points and smooth surface finishes not only facilitate easy installation but also reduce the risk of damage to cables during assembly. Thoughtful design elements, like integrated sealing options, ensure a secure, leak-proof connection—crucial in environments where moisture or dust could compromise system integrity.

Installing a trunking flange becomes a straightforward process thanks to features like pre-drilled holes and standardized mounting patterns. These aspects minimize installation time and allow for quick adjustments in complex settings. For projects that demand a bespoke fit, custom fabrication ensures that even the most challenging spaces are accommodated with precision. Such versatility underscores the importance of selecting a high-quality trunking flange that blends durability with ease of installation, particularly in South Africa’s diverse environmental conditions.

Durability and Resistance – Factors influencing longevity and environmental resistance

Durability and environmental resistance are paramount when selecting a trunking flange for cable management systems. In South Africa’s often unpredictable climate—ranging from intense heat to humid coastal conditions—these factors can significantly impact the longevity of your infrastructure. A well-designed trunking flange must withstand these challenges, ensuring reliable performance over time.

One key feature influencing durability is the choice of material. High-quality galvanized steel or UV-resistant PVC are popular options, offering exceptional resistance to corrosion and UV degradation. These materials prevent warping, cracking, or rust, even after years of exposure to the elements. Additionally, a robust trunking flange often incorporates sealed edges and reinforced fastening points, which act as formidable barriers against dust and moisture ingress.

In environments prone to extreme weather, the resistance to thermal expansion and contraction becomes crucial. Properly engineered trunking flanges accommodate these movements without compromising structural integrity. To enhance the protective qualities, some designs include integrated sealing gaskets, which create a watertight seal—vital for maintaining system integrity in moisture-prone areas.

Ultimately, the resilience of a trunking flange hinges on thoughtful design and material selection. Features such as corrosion-resistant coatings and reinforced joints extend the lifespan of the entire cable management system, safeguarding investments against South Africa’s diverse environmental conditions. When durability meets careful engineering, a trunking flange becomes more than just a component—it becomes a cornerstone of reliable infrastructure.

Applications of Trunking Flange

Industrial Uses – Heavy-duty applications in manufacturing settings

In the bustling world of heavy-duty manufacturing, where machinery roars and cables must be tamed with military precision, the trunking flange proves to be an unsung hero. Its application extends far beyond simple cable management—serving as the backbone of robust electrical systems in industrial environments. When dealing with high-voltage power distribution or intricate automation setups, a well-designed trunking flange ensures seamless connectivity and maintains structural integrity under duress.

Particularly in South Africa’s rugged industrial landscape, the durability of a trunking flange becomes paramount. These components are often subjected to extreme temperatures, moisture, and mechanical stress. Consequently, industries like mining, manufacturing, and energy rely heavily on high-quality trunking flanges to prevent downtime and safeguard infrastructure. For heavy-duty applications, selecting a trunking flange made from resilient materials such as galvanized steel or thermoplastic compounds guarantees longevity and resistance to environmental factors.

In essence, the trunking flange isn’t merely a connector; it is a vital element contributing to the safety, efficiency, and resilience of our industrial endeavors.

Commercial and Office Spaces – Cable management solutions in business environments

In busy office environments and commercial spaces, efficient cable management is essential for safety and aesthetics. The trunking flange plays a crucial role in these settings, providing secure connections and a clean, organized appearance. Properly installed trunking flanges ensure that cables stay in place, reducing clutter and minimizing tripping hazards.

For businesses looking to streamline their electrical systems, choosing the right trunking flange is key. Its design allows for easy access during maintenance, while its robust construction withstands daily wear and tear. Whether installing new cabling or upgrading existing systems, a high-quality trunking flange offers flexibility and durability.

In larger commercial projects, consider these features:

- Seamless integration with various trunking systems

- Compatibility with different cable sizes

- Easy installation with minimal disruption

Ultimately, a well-designed trunking flange enhances the safety, efficiency, and professional appearance of any business environment. It’s a small component with a significant impact—making it indispensable in modern cable management solutions.

Residential Installations – Home wiring and aesthetic considerations

In the realm of residential wiring, the humble trunking flange often goes unnoticed—yet it holds the key to a sleek, safe home environment. When installing new lighting or upgrading your electrical system, a well-chosen trunking flange ensures that cables are neatly tucked away, creating a seamless look that elevates your space’s aesthetic appeal.

A beautifully integrated trunking flange can turn a cluttered mess of wires into a minimalist masterpiece. It’s not just about looks; a sturdy flange also protects cables from accidental damage, prolonging their lifespan and maintaining safety standards. For homes in South Africa, where electrical safety is paramount, selecting the right trunking flange means reducing tripping hazards and ensuring compliance with local regulations.

Whether it’s a simple installation or a complex wiring project, the right trunking flange enhances both form and function, making it an indispensable component of modern home wiring.

Benefits of Using Trunking Flange in Cable Management

Enhanced Safety – Reducing electrical hazards

Electrical safety in cable management isn’t just a matter of convenience—it’s a crucial safeguard against potential hazards. The innovation of the trunking flange elevates safety standards by providing a secure, seamless connection point that minimizes the risk of accidental disconnections or exposed wiring. In environments where electrical faults could lead to fires or injuries, a well-designed trunking flange acts as a vital barrier, reinforcing the integrity of the entire cable system.

By ensuring cables are neatly contained and properly sealed, a trunking flange reduces the chance of electrical shocks and short circuits. Its role in preventing dust, moisture, and debris from infiltrating exposed wiring points cannot be overstated. For industries and offices across South Africa, integrating a robust trunking flange not only enhances safety but also contributes to compliance with electrical safety standards. The result? A safer workspace where risks are significantly diminished and peace of mind is assured.

Organized Wiring – Maintaining a tidy and professional appearance

In the realm of cable management, a well-crafted trunking flange isn’t just a connector—it’s the silent guardian of organized wiring, transforming chaos into clarity. When cables are neatly contained within a trunking system, the entire environment exudes professionalism and efficiency. A sturdy trunking flange ensures that every wire remains in its rightful place, preventing unsightly tangles and accidental disconnections that could spell disaster. Its seamless integration into the trunking system elevates the aesthetic appeal of any space, be it a bustling office in Johannesburg or a manufacturing plant in Durban.

The benefits of using a trunking flange extend beyond mere appearance. By maintaining tidy wiring, it significantly reduces the risk of electrical hazards, making workplaces safer for everyone. For those seeking a harmonious blend of form and function, the trunking flange is indispensable—offering durability, ease of installation, and a sleek finish. Whether for industrial applications or residential setups, this vital component ensures that cabling remains unobtrusive yet accessible, transforming mundane wiring into a work of organized art.

Protection and Durability – Safeguarding cables from damage and environmental factors

In the realm of cable management, safeguarding cables from environmental factors can mean the difference between seamless operation and costly downtime. The trunking flange plays a pivotal role in this protection, creating a resilient barrier that shields wiring from dust, moisture, and physical damage. Its robust design ensures that cables remain intact even in demanding conditions, whether in a bustling industrial plant or an outdoor commercial site.

Durability is the hallmark of a high-quality trunking flange. Crafted from materials like PVC or galvanized steel, it withstands the test of time and environmental extremes. This resilience not only prolongs the lifespan of the cable system but also reduces maintenance costs. The flange’s tight-fitting construction prevents ingress of debris and pests, which could otherwise compromise electrical safety and system integrity.

For added security, many trunking flange options feature anti-corrosion coatings or weatherproof finishes, making them ideal for outdoor or harsh environments. The seamless integration of the flange into the trunking system ensures that every cable remains securely in place, further enhancing protection against accidental dislodgement or wear and tear over time. When durability and environmental resistance are non-negotiable, the trunking flange stands out as an indispensable component in effective cable management.

Installation and Maintenance of Trunking Flange

Installation Guidelines – Step-by-step tips for proper fitting

Precision in the installation of a trunking flange can significantly influence the integrity and safety of your entire cable management system. When fitting a trunking flange, meticulous attention to detail ensures a seamless connection that withstands environmental stressors and operational demands. The process begins with verifying the compatibility of the flange size with the trunking channel, a step often overlooked but crucial for achieving a tight, secure fit.

Proper alignment of the flange during installation is paramount. It’s advisable to use appropriate fasteners and ensure they are tightened uniformly to prevent any warping or gaps. For optimal performance, consider employing sealants or gaskets where necessary, especially in environments prone to moisture or dust infiltration. This not only enhances durability but also preserves the safety standards integral to electrical systems in South Africa’s varied climate conditions.

- Ensure all mounting points are clean and free of debris before installation

- Use the correct type and size of fasteners for your specific trunking flange

- Double-check the alignment before fully securing the flange to avoid misfits that could compromise cable protection

Maintenance of trunking flanges, while seemingly straightforward, requires periodic inspection to identify signs of fatigue or corrosion. Regular tightening and replacement of worn components extend the lifespan of the entire cable management system, supporting safety and efficiency in both industrial and commercial settings. Ultimately, the art of installing a trunking flange lies in balancing precision with foresight, ensuring your installation remains resilient and fit for purpose across diverse applications.

Common Challenges and Troubleshooting – Identifying and resolving installation issues

Even the most carefully planned cable management system can face hurdles if the installation of the trunking flange isn’t spot-on. Common challenges include misalignment, inadequate sealing, or loose fasteners, all of which can compromise the safety and longevity of your setup. Troubleshooting these issues often begins with a thorough inspection—are the flange connections tight and properly aligned?

One frequent issue is warping or gaps caused by uneven tightening of fasteners. Using a torque wrench and following manufacturer guidelines can help prevent this. If moisture or dust infiltration is a concern, remember to incorporate sealants or gaskets during installation. This simple step drastically improves durability, especially in South Africa’s varied climate conditions.

- Identify any misfits or gaps at the flange connection.

- Check for signs of corrosion or fatigue, especially in industrial environments.

- Ensure fasteners are the correct type and are evenly tightened.

Addressing these common challenges early on helps maintain the integrity of your cable management system, avoiding costly repairs down the line. Regular maintenance, including tightening and replacing worn components, is essential to keep your trunking flange performing optimally in both commercial and residential settings. Troubleshooting your trunking flange with a keen eye ensures your wiring remains organized, safe, and resilient against environmental stressors.

Regular Maintenance – Best practices for longevity and performance

Ensuring the longevity and optimal performance of your cable management system begins with diligent installation and routine maintenance of the trunking flange. In environments where exposure to dust, moisture, and temperature fluctuations is common—like many South African workplaces—proper care is essential to prevent costly repairs and safety hazards.

Regular inspection of the trunking flange should be part of your maintenance routine. Look out for any misfits or gaps at the flange connection, as these can compromise the entire system’s integrity. Tighten fasteners evenly using a torque wrench, following manufacturer guidelines, to avoid warping or uneven pressure that might lead to premature failure. Incorporating sealants or gaskets during installation adds an extra layer of protection against environmental elements, especially in outdoor or industrial settings.

To streamline maintenance, consider a checklist:

- Check for signs of corrosion or fatigue.

- Ensure all fasteners are the correct type and properly torqued.

- Inspect for any damage or wear on the flange material.

Adopting these best practices not only extends the lifespan of your trunking flange but also maintains a tidy and safe wiring environment, even amid South Africa’s diverse climate challenges. Consistent upkeep guarantees that your cable management remains resilient, organized, and ready to withstand environmental stressors for years to come.

Choosing the Right Trunking Flange

Factors to Consider – Compatibility, size, environment, and load capacity

Choosing the right trunking flange involves several critical factors that can significantly impact the effectiveness of your cable management system. Compatibility with existing trunking systems is paramount; selecting a flange that fits seamlessly ensures a secure and neat installation. Size and dimensions are equally important, especially when dealing with custom or non-standard setups. An ill-fitting flange can lead to gaps, increasing the risk of environmental damage or cable wear.

Environmental conditions in South Africa, such as humidity and temperature fluctuations, should also influence your choice. A durable trunking flange made from corrosion-resistant materials will withstand these variables better, extending the lifespan of your installation. Load capacity is another key consideration—overloading a trunking flange can cause deformation or failure, compromising safety and organization.

Ultimately, understanding these factors helps in selecting a trunking flange that offers optimal performance, safety, and longevity, whether for industrial, commercial, or residential applications.

Quality Indicators – Features that differentiate high-quality flange products

When selecting a trunking flange, discerning quality is essential to ensure long-term reliability and safety. A high-quality trunking flange exhibits features that set it apart from cheaper, inferior alternatives. Durability begins with the material—premium-grade plastics or corrosion-resistant metals like stainless steel or powder-coated aluminum are often indicators of superior craftsmanship. These materials withstand South Africa’s fluctuating humidity and temperature swings, reducing the risk of environmental damage.

Another critical indicator of quality is the precision of manufacturing. Flanges with tight tolerances and seamless fittings minimize gaps, which are vital for protecting cables from dust, moisture, and mechanical stress. Additionally, look for features such as reinforced edges and robust fastening mechanisms—these details enhance load capacity and ease of installation, crucial for both industrial and commercial applications.

- Corrosion resistance

- Precise dimensions and fit

- Reinforced structural features

- Ease of installation design

By prioritizing these quality indicators, you guarantee that your trunking flange not only performs optimally but also endures the rigors of its environment, providing a resilient backbone for any cable management system. Such attention to detail ensures safety, organization, and longevity—cornerstones of professional electrical installations in South Africa’s diverse settings.

Where to Buy – Trusted suppliers and retail options

When it comes to securing a reliable cable management system, choosing the right trunking flange is not just a matter of preference — it’s a testament to your commitment to safety and durability. South Africa’s diverse environments demand products that stand the test of time, resisting corrosion, temperature fluctuations, and mechanical stress. Trusted suppliers understand this, offering a curated selection of high-quality trunking flanges that align with industry standards.

Where can you find these dependable components? Reputable hardware stores, electrical supply specialists, and specialized industrial suppliers are your best bet. These retail options often stock a variety of trunking flange types—ranging from standard to custom sizes—ensuring compatibility with your specific project requirements. To streamline your search, consider suppliers who prioritize quality indicators, like reinforced edges and precise dimensions, which are crucial for long-term performance.

- Opt for suppliers with a proven track record in South Africa’s electrical and industrial sectors.

- Choose outlets that provide detailed product specifications and after-sales support.

- Prioritize vendors offering durable, corrosion-resistant trunking flanges suitable for your environment.

In the end, selecting a trunking flange from trusted sources guarantees not only seamless installation but also enduring safety and organization for your cable infrastructure. Investing in quality today ensures your systems withstand the rigors of tomorrow’s challenges—because in cable management, excellence is non-negotiable.

Trunking Flange Trends and Innovations

Emerging Materials and Technologies – Advancements in material science

In the relentless quest for smarter, more resilient cable management solutions, the humble trunking flange is quietly evolving into a marvel of material science. With innovations emerging faster than a Johannesburg traffic jam, new materials are pushing the boundaries of durability and environmental resistance. Modern trunking flange designs now incorporate advanced composites and corrosion-resistant alloys, making them suitable for everything from bustling industrial sites to sleek office spaces.

Emerging technologies aren’t just about materials; they’re also about smarter integration. For instance, some manufacturers now embed antimicrobial coatings into trunking flanges, reducing the risk of mold and bacteria—because who wants a cable conduit that doubles as a petri dish? Furthermore, the use of lightweight yet high-strength materials means installation becomes less of a chore, even in the tightest corners. As the industry leans into eco-friendly options, biodegradable plastics and recyclable metals are beginning to make their mark.

- Enhanced corrosion resistance for outdoor and coastal environments

- Use of lightweight composites to ease installation burdens

- Integration of safety features like fire-retardant coatings

All these innovations signal a future where the trunking flange isn’t just a static component but a dynamic part of the evolving smart building ecosystem, ready to meet the demands of South Africa’s diverse electrical landscape.

Design Innovations – Enhanced functionality and ease of installation

In the ever-evolving landscape of cable management, the design innovations surrounding the trunking flange are truly transforming how we approach electrical installations. As the backbone of tidy wiring systems, the latest trends focus on enhancing functionality while simplifying installation processes. Manufacturers are now integrating ergonomic features such as snap-fit mechanisms and modular connectors into the trunking flange, making it easier to assemble and adjust on-site. This not only saves time but also reduces the risk of errors—crucial in busy industrial environments or high-traffic commercial settings.

Furthermore, new materials are elevating the durability of trunking flanges beyond traditional expectations. Lightweight composites and corrosion-resistant alloys are now standard, providing resilience against harsh outdoor and coastal conditions common in South Africa. For added safety, some designs incorporate fire-retardant coatings, ensuring compliance with stringent safety standards.

- Enhanced environmental resistance

- Ease of installation in tight spaces

- Increased safety features

These innovations collectively contribute to a more versatile, robust, and user-friendly cable management system that meets the demands of modern infrastructure.

Environmental Sustainability – Eco-friendly options and practices

As industries and urban landscapes grow more conscious of their environmental footprint, the evolution of the trunking flange reflects a significant shift towards eco-friendly cable management solutions. Manufacturers are increasingly adopting sustainable practices, integrating materials that not only meet durability standards but also promote environmental responsibility. Bio-based composites and recycled alloys are now noteworthy options, offering a reduced carbon footprint without compromising strength or resilience.

In South Africa, where harsh outdoor conditions and stringent safety regulations are common, eco-conscious trunking flange options are gaining traction. These environmentally sustainable designs often feature fire-retardant coatings made from natural, non-toxic components, ensuring safety while aligning with green initiatives. Moreover, some innovative products incorporate biodegradable elements that facilitate easier disposal and reduce long-term environmental impact.

For businesses aiming to align with global sustainability goals, choosing a trunking flange that emphasizes eco-friendly options is more than just a trend—it’s a strategic move. By prioritizing environmentally sustainable manufacturing practices, companies can contribute to a greener future and demonstrate their commitment to responsible infrastructure development. After all, thoughtful material selection and sustainable design choices are vital components of modern cable management systems—making the humble trunking flange a small but impactful part of environmental stewardship.

Frequently Asked Questions About Trunking Flange

What is the standard size of a trunking flange?

One of the most common questions about trunking flange is its standard size. Interestingly, the typical size for a trunking flange in South Africa aligns with industry standards, ensuring compatibility across different cable management systems. Most often, these flanges are manufactured to fit standard trunking dimensions, providing a seamless connection point for various cable trays and conduits.

Generally, trunking flanges come in sizes that match the width and height of the trunking system they are designed for. For example, a 100mm or 150mm flange is common for many applications, but custom sizes are also available to meet specific project requirements. This flexibility allows for efficient installation and maintenance, especially in complex electrical setups.

Understanding the size of a trunking flange is vital for ensuring a perfect fit and maintaining the integrity of the cable management system. Whether you’re working with a standard or custom trunking flange, always verify the dimensions against your project specifications. Accurate sizing not only simplifies installation but also enhances the durability and safety of the entire system.

Can trunking flanges be reused or recycled?

Recycling and reusing are integral principles in sustainable electrical installations, especially when it comes to components like the trunking flange. These versatile fittings are often designed with durability in mind, making them suitable candidates for reuse in multiple projects. In South Africa, where eco-conscious practices are gaining momentum, understanding whether a trunking flange can be recycled is vital for both environmental and economic reasons.

Generally, trunking flanges made from materials such as galvanized steel, PVC, or aluminum can be recycled, provided they are free from damage or corrosion. It’s important to verify the condition of the flange before reuse, as compromised parts may jeopardize the safety and integrity of the entire cable management system. Many suppliers in South Africa facilitate recycling programs or offer refurbishment options, encouraging a circular approach to electrical components.

- Recycling options often include collection, refurbishment, or repurposing of used trunking flanges.

- Proper disposal is crucial to prevent environmental contamination and promote sustainability.

By choosing high-quality trunking flanges that can be reused or recycled, professionals can significantly reduce waste and promote greener practices within the electrical industry. In a landscape where safety and durability are paramount, reusing a well-maintained flange not only supports eco-friendly initiatives but also ensures continued performance and reliability of the cable management system in South Africa’s diverse environments.

How do I ensure compatibility with my existing cable trunking?

Frequently Asked Questions About Trunking Flange: How Do I Ensure Compatibility with My Existing Cable Trunking?

Matching a trunking flange with existing cable trunking might seem straightforward, but it can be more complex than it first appears. The key is understanding the specifications and compatibility standards that ensure a seamless fit, safety, and optimal performance. In South Africa, where diverse environments demand versatile electrical solutions, getting this right is crucial.

First, verify the dimensions of your current trunking system, including width, depth, and flange thickness. Ensuring these measurements align with the new trunking flange helps prevent gaps or loose fittings that could compromise safety. Additionally, check the material compatibility—whether galvanized steel, PVC, or aluminum—to maintain durability and resistance against environmental factors.

Some professionals recommend creating a checklist before purchasing:

- Confirm the size and shape of your cable trunking

- Match the flange’s mounting type to your existing system

- Ensure the material is suitable for the installation environment

By paying attention to these details, you can confidently select a trunking flange that integrates perfectly with your current setup, ensuring both safety and efficiency in your electrical network. Remember, compatibility isn’t just about fitting; it’s about creating a dependable, long-lasting cable management system that withstands South Africa’s varied conditions.

0 Comments