A steel conduit is a type of metal tubing that provides an enclosure for electrical wiring. It is commonly used in industrial locations as it protects the wires from various conditions such as high impact and strong temperatures, which can otherwise damage the wiring. There are multiple different types of steel conduit tubing available in the market, each with its own characteristics and benefits. To help you choose the right one for your needs, here are some of the most important things to keep in mind.

The biggest benefit of using a steel conduit is that it will give you the best protection for your wiring. This is because steel is one of the strongest materials that can withstand different kinds of harsh environments and conditions, including high impacts and temperatures.

Additionally, steel conduit is a non-combustible material that will not burn easily. It also has a long lifespan and is extremely resilient. This means that it can withstand the elements better than other wiring methods, making it one of the safest options for commercial and industrial locations.

Another advantage is that it can be installed in both new and existing buildings. While other wiring methods may have specific restrictions, this is not the case for steel conduit, as it can be installed anywhere. This flexibility makes it easier to install wiring in any building, saving time and money.

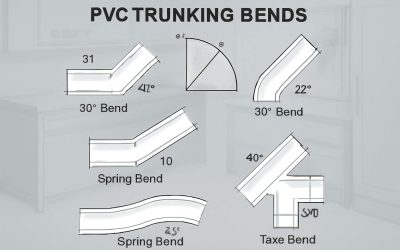

Furthermore, steel conduit can be fitted with different kinds of fittings to meet different requirements. For example, some types of fittings can be used to increase the level of liquid impermeability in the conduit. This is very useful in locations where the conduit will be exposed to a lot of moisture, such as kitchens or tools.

Other kinds of fittings can be used to add more security to the electrical conduit. For instance, locking fittings can be used to prevent unauthorized access to the wiring inside of the steel conduit. This is a very useful feature for commercial and industrial locations, as it will prevent workers from tampering with the wiring without authorization.

In addition, there are other kinds of fittings that can be used to reduce the amount of noise produced by the electric wires in the steel conduit. This is especially useful for noisy locations, such as factories. Finally, there are some types of fittings that can be used to protect the conduit from the effects of electromagnetic fields. A recent study by the Georgia Institute of Technology found that steel conduit can shield 60 Hz EMFs by up to 95 percent, while other materials only decrease these fields by about 5 percent.

There are many other reasons why a construction company should use steel conduit over other types of wiring. Besides providing a good level of protection, it can also save the contractor money over the life of the building. This is because it doesn’t require a ground wire, which would normally be required for other types of wiring.

0 Comments