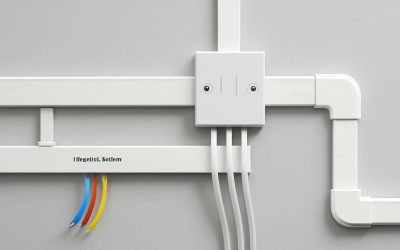

PVC trunking is a type of plastic pipe that can be used for wiring and other applications. It is a strong and durable option, and can help to improve safety and efficiency in many industries. It is also environmentally friendly and recyclable.

There are several different types of pvc trunking available, and each type has unique features and benefits. The main advantages of pvc trunking include its strength, durability, and ease of installation.

Typically, pvc trunking is made from a tough polymer called ethylene-propylene copolymer. This material is known for its tensile strength and flexibility, making it an ideal choice for most industrial applications.

Cellular PVC is a non-toxic, lightweight, self-extinguishing, and recyclable alternative to traditional building materials such as wood. It is a good choice for homeowners and builders who want to reduce maintenance costs, and it is an excellent choice for new construction where a high-quality finish is desired.

It is a relatively inexpensive material that looks, feels, and paints like wood, but it is much stronger than wood. It is also fire retardant, water resistant, and can withstand a variety of chemicals.

The most common cellular PVC is manufactured by free-foam extrusion, but it can also be made using Celuka technology. This technology combines a heat-activated blowing agent with an expansion agent to create a gas-filled cell structure within the PVC.

These cellular PVC products are dimensionally stable, and they have a higher strength and stiffness than free-foam pvc. These cellular PVC products are used for everything from sheeting and dimensional lumber to trim form and moldings.

They can also be coated with other surfacing resins to provide gloss, color, or scuff resistance. Some cellular PVC is even coextruded with a urethane coating to improve its surface appearance and increase durability.

Another advantage of cellular PVC is its ability to be cut, rout, and fasten just like wood. This makes it easy to use for a wide range of construction projects and renovations, and its smooth surfaces are easy to clean and maintain.

A few manufacturers offer a complete line of white, solvent-free, two-component methyl methacrylate-based adhesives specifically designed for cellular PVC. They come in fast- and slow-curing formulations as well as low-viscosity laminating grades that can be used to build large cross-sectional profiles.

Methyl methacrylate-based adhesives for cellular PVC are the preferred bonding agents for most cellular PVC fabrications and installations. They are available in both liquid and spray-applied forms, and can be applied over the entire length of a PVC product with minimum bond lines. They are also suitable for a variety of other applications, including filling fastener holes and creating blends or fillets between adjoining pieces.

Most cellular PVC is compatible with a wide variety of fasteners, including common structural metals such as stainless steel and aluminum, brass, copper, and titanium. They are also resistant to corrosive environments and are suitable for many industrial applications such as oil refineries, chemical plants, and marine facilities.

0 Comments