When you are looking to keep your electrical wiring organised and safe, it’s essential to use the right cable management systems. These systems are designed to protect your cables from snagging, tripping, and falling. They also help prevent fires and damage to your equipment. They are an important part of any industrial or commercial installation.

Getting the Right Material For Your Steel Trunking

When it comes to deciding on your cable trunking, you should be sure that you choose the right material for the task. The wrong materials can lead to corrosion, shortening the life of your equipment. You should also make sure that you purchase trunking that is able to withstand different climates and environments.

Galvanised Trunking Is Not The Best Option For Cable Management

While galvanised trunking offers several benefits, it can also pose risks. This is especially true when it comes to its durability and service life.

If you store your galvanised trunking in a wet environment, it can develop a white powdery coating that looks like rust. This is because fresh zinc on the surface of the metal is vulnerable to moisture and water.

Luckily, you can avoid this by opting for power-coated or stainless steel trunking instead of galvanised ones. These types of materials can also withstand a wider range of climates and environments, reducing your risk of rusting your equipment.

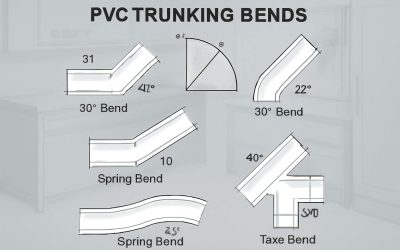

How to Bend Steel Conduit

To form a double 90deg angle in your conduit, it is important to use the correct former. This is because the conduit needs to be positioned at a certain distance from the centre of the former. For this purpose, you can use a try-square to mark off the desired position. Once the former is in place, you can then use a bending machine to create a curve.

This can be done in a few ways, depending on the size of the conduit. For smaller conduits, you can simply place the former in the bending machine and pull down on it until it forms a curve. For larger conduits, you’ll need to use a ratchet bender to bend the steel.

How To Measure The Space Required For Trunking

If you are using steel trunking, you must know how much space it needs to accommodate your cables. You must also consider the type of supports that will be used for your trunking. This will impact the number of cables that you can install in your system.

The maximum number of cables that you can put in a trunking system is 45% of its total capacity. The remaining 45% should be left unoccupied space. This will ensure that you can run the necessary cables in your system without causing any damage to them.

How To Measure The Space Required for Your Trunking

You can get the exact measurements you need to determine the amount of space your steel trunking needs by using an electronic meter. This device is easy to use and has a variety of functions. Moreover, it is compatible with many software applications.

0 Comments